| ZK61 alloy powder spherical | |

| Product No | NRE-60102 |

| Purity | 99.9% |

| Mesh | 15-53 mesh |

| Color | Silver Gray |

| ZK61 | |||||||||

| Composition | Mg | Zr | Zn | Fe | Mn | Ni | Si | Cu | Al |

| wt% | 94.46 | 0.33 | 5.1953 | 0.0035 | 0.0055 | 0.003 | 0.0007 | 0.0010 | 0.0006 |

ZK61 alloy powder spherical

Introduction

ZK61 is a magnesium-based alloy that is composed primarily of magnesium (Mg), with zinc (Zn) and zirconium (Zr) as its main alloying elements. Small additions of other elements, such as manganese (Mn), rare earth metals, and occasionally aluminum (Al), are also present to enhance specific properties like corrosion resistance, strength, and workability. ZK61 is highly regarded for its lightweight, high strength-to-weight ratio, excellent creep resistance, and superior corrosion resistance, making it an attractive choice for industries where material performance is crucial, such as aerospace, automotive, marine, and medical applications.

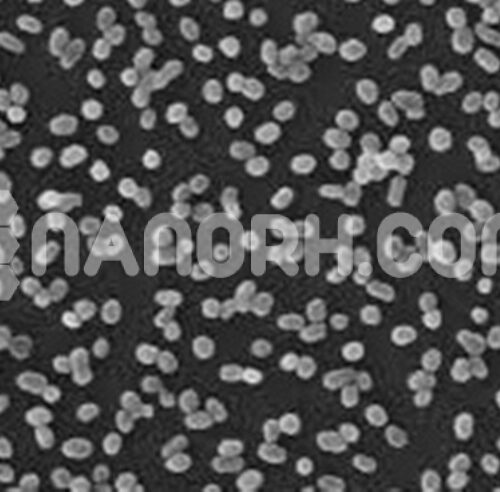

When ZK61 alloy is processed into spherical powder, its properties are further optimized for modern manufacturing techniques like additive manufacturing (3D printing), metal injection molding (MIM), and powder metallurgy (PM). The spherical shape of the powder particles significantly improves their flowability, packing density, and uniformity. These attributes are essential for producing complex, high-performance parts with fine geometries, which can be difficult to achieve with traditional manufacturing processes. Spherical ZK61 powder is particularly useful in industries that demand lightweight, high-performance materials capable of withstanding extreme operational conditions while offering aesthetic flexibility and design freedom.

Spherical ZK61 alloy powder is produced using advanced techniques like gas atomization, water atomization, or rotary atomization, which involve rapidly cooling molten metal to create fine, uniform spherical particles. The spherical particles produced are often in the range of 10-100 microns, which are ideal for powder-based manufacturing methods. This uniformity ensures consistent part quality and repeatability during the manufacturing process. The spherical nature of the powder also ensures better packing density in powder beds during additive manufacturing, which results in high-density prints with minimal porosity. The ability to achieve homogeneous material properties across all layers is a crucial advantage when using ZK61 powder in advanced manufacturing techniques.