| Zirconium Pellets | |

| Product No | NRE-62068 |

| CAS No. | 7440-67-7 |

| Formula | Zr |

| Size | 1/4″ Dia. x 1/4″ Length (Can be Customized) |

| Quantity | 50g, 100g |

| Purity | 99.99% |

| Molecular Weight | 91.224 g/mol |

| Density | 6.49 g.cm-3 |

| Melting Point | 1852 °C |

| Boiling Point | 3580°C |

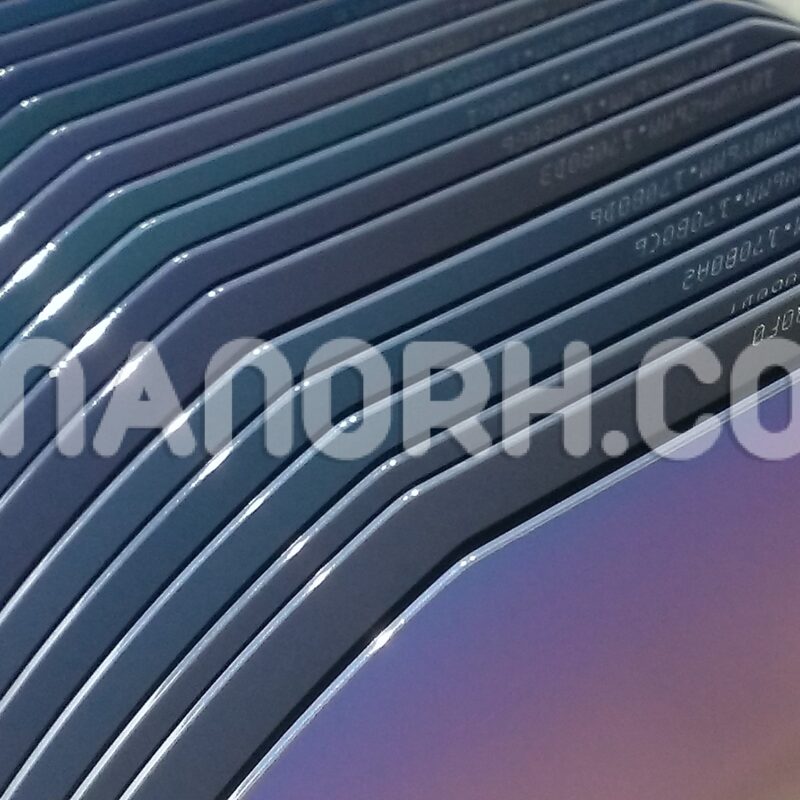

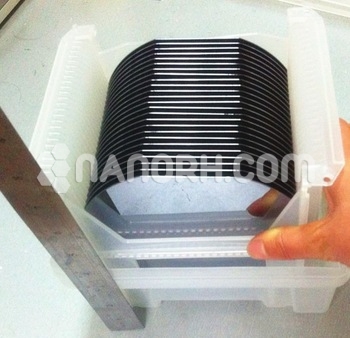

Zirconium Pellets

Introduction:

Zirconium pellets are solid forms of zirconium, a lustrous, silvery-white metal known for its high corrosion resistance, strength, and stability at high temperatures. Zirconium is primarily obtained from the mineral zircon and is often used in applications where resistance to heat and corrosion is crucial. Zirconium pellets are commonly used in various industrial processes and materials.

Applications

Nuclear Applications: One of the primary uses of zirconium is in the nuclear industry. Zirconium alloys are used as cladding for nuclear fuel rods due to their excellent corrosion resistance and low neutron absorption, making them ideal for maintaining the integrity of the fuel.

Chemical Processing: Zirconium is highly resistant to corrosion and is used in various chemical processing applications, including reactors, heat exchangers, and piping systems. Zirconium pellets can be utilized in the manufacturing of these corrosion-resistant components.

Aerospace: In the aerospace industry, zirconium is used in components that require high strength and resistance to heat. Its properties make it suitable for applications in engines and other high-performance systems.

Medical Devices: Zirconium is biocompatible, making it valuable in the medical field for implants and surgical instruments. Its resistance to corrosion and wear enhances the longevity of medical devices.

Ceramics: Zirconium dioxide (zirconia) is often used in advanced ceramics and is known for its high thermal stability and strength. Zirconium pellets can be processed to produce zirconia, which is used in applications such as dental crowns and cutting tools.

Additive Manufacturing: Zirconium is increasingly used in additive manufacturing processes, where its unique properties can be leveraged to create high-performance components for various industries.