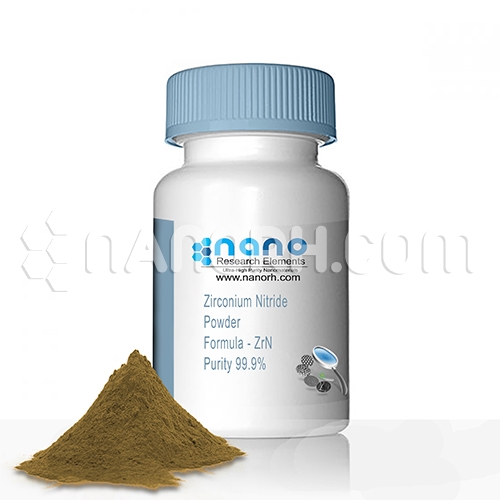

| Zirconium Nitride Powder | |

| Product No | NRE-11304 |

| CAS No. | 25658-42-8 |

| Formula | ZrN |

| Density | 7.09 g/cm³ |

| APS | <40µm (Can be Customized) |

| Purity | 99.9% |

| Form | Powder |

| Molecular Weight | 105.2307 g/mol |

| Certificate Of Analysis | |

| Assay | 99.9% |

| Mn | 0.02% |

| Al | 0.01% |

| Fe | 0.03% |

| O | 0.02% |

| C | 0.01% |

| Cr | 0.01% |

Zirconium Nitride Powder

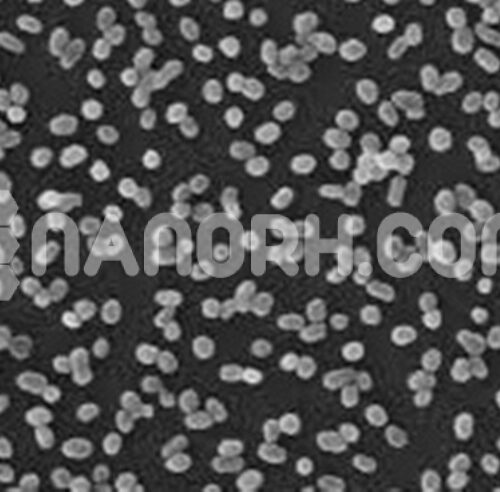

Zirconium nitride powder is a high-performance ceramic compound composed of zirconium and nitrogen. It is part of a broader family of transition metal nitrides, which are known for their exceptional mechanical properties, thermal stability, and corrosion resistance. Zirconium nitride is typically synthesized by reacting zirconium metal with nitrogen gas at high temperatures, or by reacting zirconium salts with nitrogen-containing compounds.

Key Features of Zirconium Nitride Powder

High Melting Point: ZrN has an extremely high melting point (around 3,300°C), which makes it highly suitable for applications in extreme heat environments, such as aerospace and nuclear industries.

Excellent Thermal Stability: The material retains its properties even under high-temperature conditions, making it a thermal barrier material in applications like heat shields and turbine blades.

Hardness and Wear Resistance: With a hardness between 8 and 9 on the Mohs scale, zirconium nitride is abrasion-resistant, making it useful for cutting tools, coatings, and wear-resistant components.

Corrosion and Oxidation Resistance: ZrN is highly resistant to corrosion and oxidation, even in aggressive environments, which is essential for aerospace, chemical processing, and nuclear reactors.

Electrical Conductivity: Unlike many ceramic materials, zirconium nitride is a metallic conductor of electricity, which allows it to be used in electronic applications that require both ceramic stability and electrical conductivity.

Low Friction Coefficient: Zirconium nitride coatings provide a low friction surface that reduces wear in mechanical systems and extends the lifespan of components.