| Zirconium Carbide Sputtering Targets | |

| Product No | NRE-43297 |

| CAS No. | 12070-14-3 |

| Formula | ZrC |

| Molecular Weight | 103.23 |

| Purity | >99.9% |

| Density | 6.73 g/cm3 (24 °C) |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Zirconium Carbide Sputtering Targets

Introduction

Zirconium carbide sputtering targets is a ceramic material known for its exceptional hardness, high melting point, and thermal stability. These properties make it an ideal candidate for use in sputtering targets, which are essential for thin-film deposition processes in various high-tech applications. Zirconium carbide is particularly valued in environments where wear resistance and thermal performance are critical.

Applications

Wear-Resistant Coatings:

ZrC is used to create hard coatings for tools and components that experience high friction and wear, enhancing their durability.

Thermal Barrier Coatings:

Employed in aerospace applications to protect components from extreme temperatures, such as in jet engines and turbine blades.

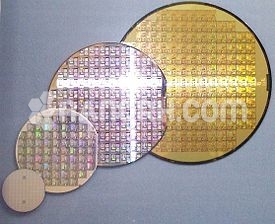

Semiconductor Manufacturing:

Used in the deposition of thin films for interconnects and gate electrodes, offering excellent electrical properties and reliability.

Optical Coatings:

Suitable for coatings that require high hardness and scratch resistance, used in lenses and protective covers.

Plasma Facing Materials:

Utilized in fusion reactors and other high-temperature applications due to its thermal stability and resistance to erosion.

Biomedical Applications:

Investigated for biocompatible coatings in medical implants, where durability and corrosion resistance are essential.

Nanotechnology:

Used in the fabrication of nanoscale devices, benefiting from the precise deposition control that sputtering allows.