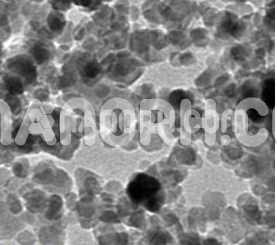

Zirconium Carbide Powder / ZrC Powder (ZrC, High Purity 99.9%, 400-1200nm, Cubic)

Zirconium carbide can be used in new insulation thermostat textiles, nylon, fiber, hard alloy, nano-structured parts and devices: such as metallurgy, chemical industry, machinery, aviation, aerospace and energy industries using high temperature and corrosion resistant; The surface coating of metal and other materials; Composite materials: such as the fabrication of metal matrix, ceramic matrix, polymer nanocomposites; Sintering additives, grain refining agents or nucleating agents..

| Zirconium Carbide Powder | |

| Product No | NRE-5270 |

| CAS No. | 12070-14-3 |

| Formula | ZrC |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 103.2347 g/mol |

| Density | 6.7 g/cm3 |

| Melting Point | 3,532 °C |

| Boiling Point | 5,100 °C |

ZrC Powder Features:

Applications

Zirconium carbide powder is a highly refractory ceramic material known for its remarkable hardness, high melting point, and excellent thermal and chemical stability. These properties make ZrC powder a valuable material in a variety of advanced industrial applications. The powder form of ZrC, with its large surface area, is particularly useful in applications where high performance under extreme conditions is required.

Here are the primary applications of Zirconium Carbide (ZrC) powder:

Aerospace and Defense

Hypersonic Materials: Zirconium carbide is widely used in aerospace applications, particularly in hypersonic flight systems, such as re-entry vehicles, missiles, and space exploration vehicles. ZrC powder is used to create coatings and composite materials for heat shields. Its extremely high melting point (around 3,400°C) allows it to withstand the intense heat generated during high-speed atmospheric re-entry or high-temperature missile propulsion.

Armored Materials: Due to its hardness, ZrC is used in the manufacturing of advanced armor materials. It provides superior protection against ballistic impacts and extreme thermal conditions. Zirconium carbide is often used in conjunction with other materials like ceramics to enhance the durability and resistance of military vehicles and protective gear.

Nuclear Industry

Nuclear Reactor Components: ZrC is used in the nuclear industry due to its high thermal conductivity and resistance to corrosion. It is used as a coating for nuclear fuel rods, enhancing their stability and performance under the high-temperature, high-radiation conditions of a reactor.

Moderator in Nuclear Reactors: Zirconium carbide, along with zirconium alloys, is also investigated for use as a moderator in advanced nuclear reactors, where it helps manage neutron flux and improve reactor efficiency.

Cutting Tools and Wear-Resistant Coatings

Cutting and Grinding Tools: ZrC powder is used to produce extremely hard cutting tools and abrasives. Its high hardness and wear resistance make it ideal for machining difficult materials, especially in industries like aerospace, automotive, and metalworking.

Wear-Resistant Coatings: ZrC is often applied as a wear-resistant coating in industries where equipment is subjected to high-stress conditions. Its hardness and resistance to wear make it a good choice for improving the longevity of machine components such as valves, pumps, and turbine blades.