|

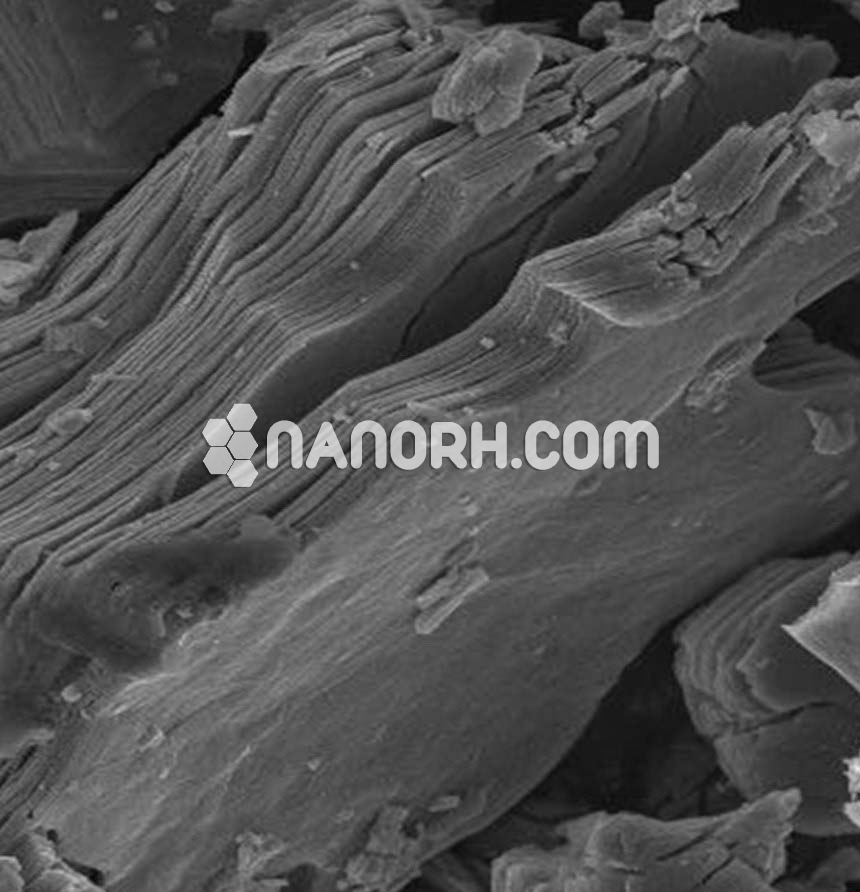

VCrAlC MAX Phase Powder |

|

| Product No. | NRE-58029 |

| CAS No. | NA |

| Formula | VCrAlC |

| Molecular Weight | NA |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

VCrAlC MAX Phase Powder

Applications

Aerospace and High-Temperature Applications

Heat Shields: VCrAlC is used in aerospace components, especially in heat shields and turbine blades where materials are subjected to extreme temperatures. The thermal stability and oxidation resistance of VCrAlC make it ideal for such applications in environments with high-speed airflow and heat.

Jet Engines and Rocket Propulsion: Due to its high mechanical strength and thermal resistance, VCrAlC can be used in jet engines and rocket propulsion systems, where materials need to withstand high thermal and mechanical stress.

Cutting Tools and Wear-Resistant Coatings

Cutting Tools: The hardness and wear resistance of VCrAlC make it suitable for use in cutting tools, including milling inserts, drill bits, and saw blades. These tools are used in machining operations for both metalworking and mining.

Wear-Resistant Coatings: VCrAlC can be used as a protective coating on equipment that experiences high abrasion, such as pumps, valves, machinery, and industrial tools. These coatings provide corrosion resistance and wear resistance, increasing the longevity of critical components.

Electronics and Energy Storage

Energy Storage Devices: VCrAlC is a potential material for energy storage devices, including batteries and supercapacitors. The electrical conductivity and thermal stability of VCrAlC help improve the efficiency and lifespan of energy storage systems.

Electronics and Conductive Coatings: VCrAlC is used in electronic components such as capacitors, resistors, and sensor coatings. Its electrical conductivity is beneficial for use in conductive coatings or as electrode material in energy storage devices.

Tribological (Friction and Wear) Applications

Bearings and Gears: VCrAlC is useful in tribological applications, including the production of bearings, gears, and sliding components. These parts are exposed to constant friction and wear, and VCrAlC’s resistance to these factors makes it an excellent choice for high-performance applications in industries like automotive, machinery, and industrial manufacturing.

Automotive Parts: The wear resistance and mechanical strength of VCrAlC make it suitable for automotive components such as pistons, camshafts, and valves, which experience high friction and extreme thermal conditions.