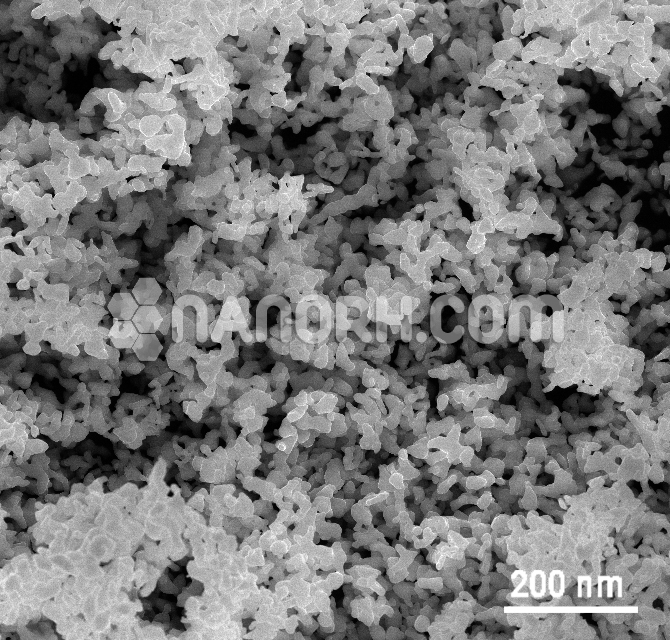

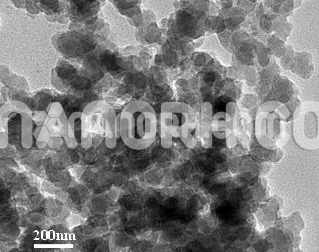

Vanadium Carbide (VC) Nanopowder / Nanoparticles (VC, 99.9%, 600-800nm, Gray, Cubic Crystal Structure)

| Vanadium Carbide (VC) Nanopowder / Nanoparticles | |

| Product No | NRE-5250 |

| CAS No. | 12070-10-9 |

| Formula | VC |

| APS | <800nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray |

| Molecular Weight | 62.9522 g/mol |

| Density | 5.77 g/cm3 |

| Melting Point | 2810 °C |

| Boiling Point | NA |

Vanadium Carbide (VC) Nanopowder / Nanoparticles Properties and Applications:

Vanadium carbide, VC, is a to a great degree hard unmanageable earthenware material. It is financially utilized as a part of hardware bits cutting instruments. It resembles dim metallic powder with a cubic gem structure. Vanadium carbide is synthetically steady and has great high-temperature property.

Wear-Resistant Coatings and Surface Treatments

Vanadium carbide nanoparticles are widely used in wear-resistant coatings and surface treatments due to their extreme hardness and durability.

Cutting Tools: VC nanoparticles are used in cutting tools such as drills, mills, and saw blades. The nanoparticles significantly improve the hardness and wear resistance of the tools, extending their lifespan and improving their efficiency in machining hard metals and alloys.

Grinding and Polishing Materials: The hardness of VC nanoparticles makes them ideal for abrasive materials like grinding wheels, polishing compounds, and other surface finishing tools. They help enhance the efficiency and precision of these materials in processes requiring fine surface finishes.

Coatings for Industrial Machinery: VC nanopowders are applied as coatings on industrial machinery components, such as pumps, valves, and rollers, to enhance their wear resistance. These coatings help reduce friction and abrasion, thereby improving the durability of components in high-stress environments.

Aerospace and High-Temperature Applications

The high melting point and thermal stability of VC nanoparticles make them ideal for aerospace and high-temperature industrial applications.

Aerospace Components: VC nanoparticles are used in aerospace components like turbine blades, nozzles, and heat shields, which are subjected to high temperatures, mechanical stress, and thermal cycling. The stability of VC ensures that the materials retain their structural integrity under extreme conditions.

Heat-resistant Coatings: VC nanopowders are applied in thermal spray coatings for components that need to withstand prolonged exposure to high temperatures. They are used in industrial furnaces, gas turbines, and jet engines, where heat resistance is essential for maintaining efficiency and reliability.

Energy Storage and Conversion

VC nanoparticles are also explored for their potential in energy storage and conversion technologies.