|

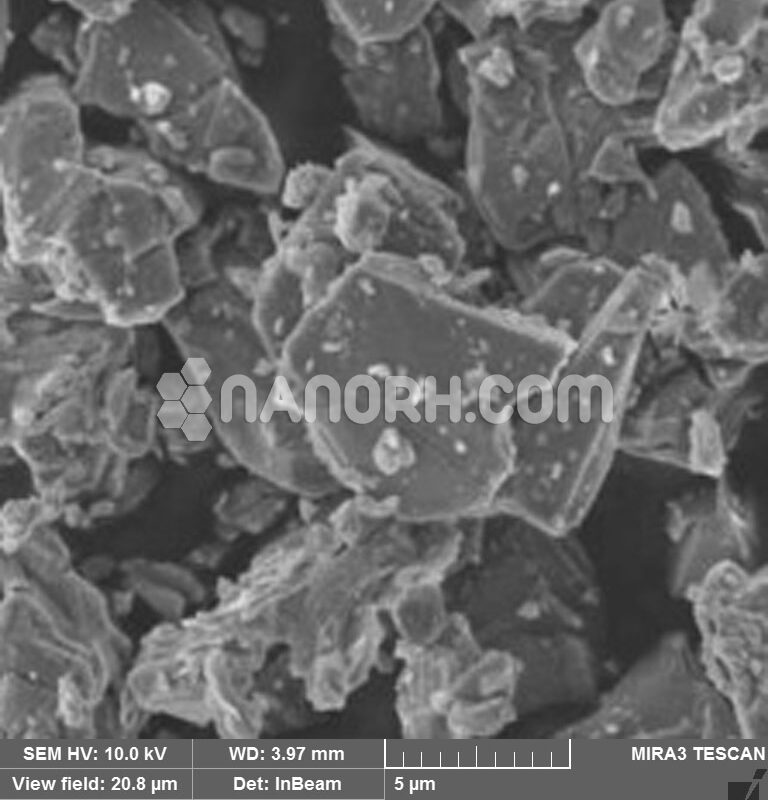

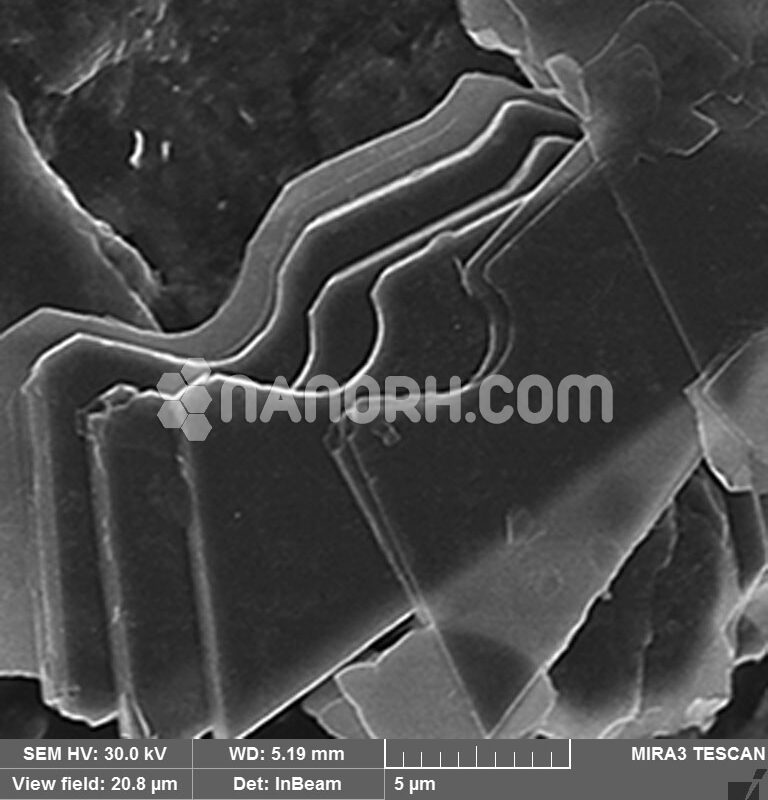

Vanadium Aluminum Carbide MAX Phase Powder |

|

| Product No. | NRE-58016 |

| CAS No. | 12179-42-9 |

| Formula | V2AlC |

| Molecular Weight | 140.87 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

|

Certificate of Analysis |

|

| V | 72.3% |

| Al | 19.1% |

| C | 8.5% |

| Sn | 0.03% |

| B | 0.02% |

| Cr | 0.01% |

| O | 0.03% |

Vanadium Aluminum Carbide MAX Phase Powder

Applications

Aerospace and High-Temperature Applications

High-Temperature Components: V₂AlC MAX phase powder is highly suitable for aerospace applications, where materials are subjected to extreme temperatures and mechanical stress. The material’s thermal stability and mechanical strength make it ideal for use in components such as heat shields, turbine blades, and engine components.

Jet Engine Parts: Due to its resistance to oxidation and high temperatures, V₂AlC is an excellent choice for parts in jet engines and aircraft components exposed to high heat and mechanical stress.

Electronics and Electrical Conductivity

Electrical Conductors: V₂AlC MAX phase powder, with its metallic-like electrical conductivity, is used in electronic devices where materials need to conduct electricity while also withstanding high temperatures and harsh environments.

Conductive Films: It can be used to create transparent conductive films for use in touchscreens and solar cells, where both high electrical conductivity and thermal resistance are crucial.

Cutting Tools and Wear-Resistant Coatings

Hard Coatings: Due to its hardness and wear resistance, V₂AlC MAX phase powder is ideal for cutting tools, abrasive surfaces, and wear-resistant coatings in industries like manufacturing, machining, and construction.

Tool Inserts and Drills: It is used in the fabrication of tool inserts, drills, and milling cutters that require both mechanical toughness and resistance to wear under high-pressure conditions.

Corrosion-Resistant Materials

Protective Coatings: V₂AlC is highly resistant to oxidation, which makes it useful in applications requiring corrosion-resistant coatings. For example, it can be applied as a coating to metal parts in environments exposed to high temperatures and oxidative conditions (such as in marine or chemical processing industries).

Corrosion Resistance in Chemical Plants: The material’s resistance to corrosive substances and high temperature makes it ideal for applications in chemical reactors, heat exchangers, and pipeline materials.