| Tungsten Carbide Sputtering Target | |

| Product No | NRE-43167 |

| CAS No. | 12070-12-1 |

| Formula | WC |

| Molecular Weight | 195.86 g/mol |

| Purity | 99.9% |

| Density | 15.63 g/cm3 |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

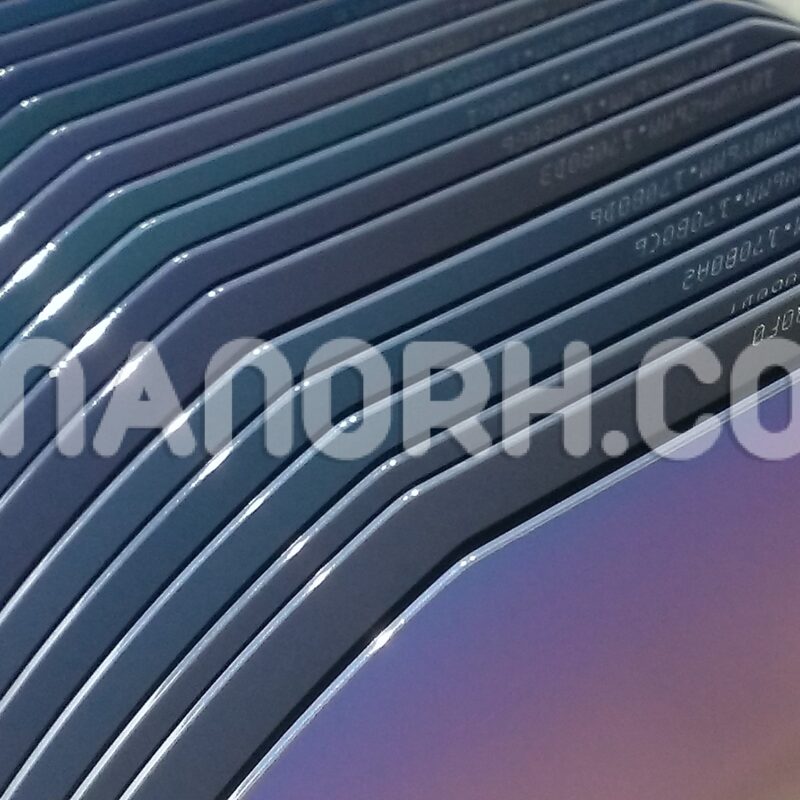

Tungsten Carbide Sputtering Target

Introduction:

Tungsten carbide sputtering target is a robust and dense ceramic material known for its exceptional hardness and wear resistance. Composed of tungsten and carbon, it is commonly used in various industrial applications where durability and performance are critical. Sputtering targets made from tungsten carbide are utilized in physical vapor deposition (PVD) processes to create thin films with superior properties for diverse applications.

Applications:

Cutting Tools: Tungsten carbide is widely used in the manufacture of cutting tools and inserts, providing outstanding wear resistance and durability during machining operations.

Wear-Resistant Coatings: WC sputtering targets are used to produce coatings for components such as pumps, valves, and bearings, enhancing their resistance to abrasion and prolonging service life.

Mining and Drilling Equipment: The toughness and hardness of tungsten carbide make it ideal for tools used in mining and drilling, where equipment faces harsh conditions and high wear rates.

Aerospace Components: Tungsten carbide coatings are applied to aerospace components to improve wear resistance and performance under extreme temperatures and pressures.

Biomedical Applications: Tungsten carbide is being explored for use in biomedical devices and implants due to its hardness and potential biocompatibility.