| Tungsten Carbide Powder | |

| Product No | NRE-11269 |

| CAS | 12070-12-1 |

| Purity | 99.95% |

| APS | <70µm (can be customized) |

| Molecular Weight | 195.85g/mol |

| Density | 15.63 g/cm3 |

| Color | Grey-Black |

| Molecular Formula | WC |

| Melting Point | 2785-2830°C |

| Boiling Point | 6000 °C |

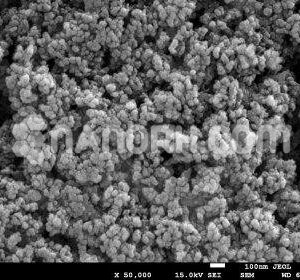

Tungsten Carbide Powder

Tungsten carbide powder as the main raw material with high hardness and excellent wear resistance is widely used in drills, molds, needles, cutting tools and other special processing industries. Due to the high bonding strength and fine microstructure between WC powder and metal binder phase, cemented carbide simultaneously combines the properties of ceramic and metal, which has high toughness, good strength and toughness, Excellent hardness. For this reason, many studies have been carried out on the optimal preparation of composite powders, on the most appropriate proportions of the bonding phases, on the effects of doping with other elements and on the best size and morphology, among others of the toilet. Granules, in order to determine the hardness to be improved and the toughness of cemented carbides. Among many factors, the size of the WC powder has the greatest influence on the mechanical properties of cemented carbides. The hardness and flexural strength of cemented carbides increase as the proportion of WCpowder increases. The size of conventional and WC powder is 4.0.2 µm, respectively. The samples were prepared by mixing two types of WC powders with different mass ratios between conventional and ultrafine powders. The particle size of the WC powders directly determines the particle size of the WC in the carbide during the sintering process. And the WC grain size is related to the mechanical properties of sintered cemented carbides. The hardness of carbide increases with the mass fraction of ultrafine WC powder. Flexural strength showed the same trend as hardness. Tungsten carbide powder improve sintering performance and improve carburizing mechanical properties.