Tungsten Carbide Cobalt Powder (Agglomerated and Sintered -Thermal Spray, 28um)

Used for rolls, gate and ball valves, oil field equipment, hydraulic cylinders, compressor shafts, mud pump rotors etc….

| Tungsten Carbide Cobalt Nanopowder | |

| Product No | NRE-5241 |

| CAS No. | 12070-12-1/7440-48-4 |

| Formula | WC/Co |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Black |

| Molecular Weight | 254.78 g/mol |

| Density | 3.9 g/cm3 |

| Melting Point | 2867°C |

| Boiling Point | 6000°C |

Tungsten Carbide Cobalt Powder

WC/10Co/4Cr: Used for rolls, gate and ball valves, oil field equipment, hydraulic cylinders, compressor shafts, mud pump rotors etc.

Introduction

Tungsten carbide cobalt Nanopowder is a composite material made by combining tungsten carbide (WC), a hard ceramic compound, with cobalt (Co), a ductile metal. This combination creates a material that exhibits the exceptional hardness and abrasion resistance of tungsten carbide, along with the toughness and impact resistance of cobalt. The result is a high-performance material widely used in various industrial applications where durability, resistance to wear, and the ability to withstand extreme conditions are critical.

Composition and Structure

The primary components of WC-Co powder are tungsten carbide (WC), which is formed by the reaction of tungsten with carbon, and cobalt (Co), which acts as a binder to hold the tungsten carbide particles together. The typical composition of WC-Co powder ranges from 70% to 98% tungsten carbide by weight, with the remaining portion being cobalt. The amount of cobalt in the mix can vary depending on the application requirements, as more cobalt increases toughness, while more tungsten carbide increases hardness and wear resistance.

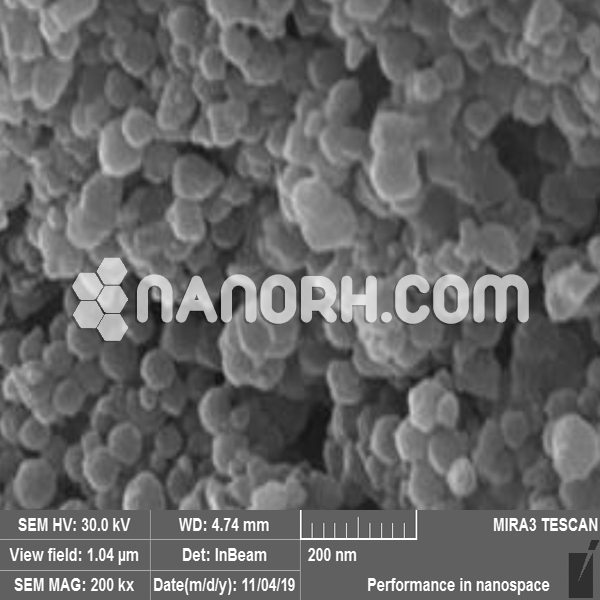

At the microscopic level, WC-Co powders consist of fine tungsten carbide particles that are bonded together by cobalt in a matrix structure. This mixture of hard tungsten carbide grains and tough cobalt matrix creates a balance between hardness and toughness, making WC-Co powder an ideal material for a wide range of demanding applications.