| Tungsten Carbide Cobalt Alloy Powder | |

| Product No | NRE-9045 |

| CAS No. | 12070-12-1 / 7440-48-4 |

| Formula | WC-Co |

| Molecular Weight | 254.7839 g/mol |

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | NA |

| Color | Gray |

| Melting Point | NA |

| Boiling Point | NA |

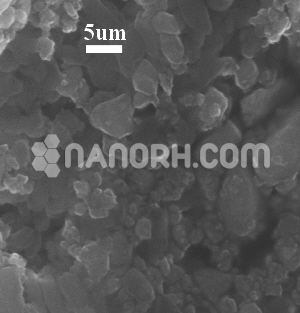

Tungsten Carbide Cobalt Alloy Powder

Introduction

Tungsten Carbide Cobalt Alloy Powder (often referred to as WC-Co alloy powder) is a composite powder consisting of tungsten carbide (WC) and cobalt (Co). This material is widely recognized for its superior hardness, wear resistance, and strength, making it a go-to solution for applications in industries where components face extreme stress, abrasion, and high temperatures.

The combination of tungsten carbide (WC) and cobalt (Co) in this powder offers a unique balance of hardness and toughness. Tungsten carbide is one of the hardest materials available, providing exceptional wear resistance and strength, while cobalt acts as a binder, improving toughness and ductility, making the material more resistant to impact and fracture.

Composition

Tungsten Carbide (WC):

Tungsten carbide is a very hard, dense ceramic material that provides exceptional wear resistance and high strength. It is often used in environments where abrasion, erosion, and high stress are present. Its high hardness makes it ideal for cutting, drilling, and other machining applications.

Cobalt (Co):

Cobalt is used as a binder in the composite material to hold the tungsten carbide particles together. It provides toughness, ductility, and impact resistance, making the material less brittle and more durable under impact and shock loads. Cobalt also enhances the corrosion resistance of the alloy, particularly in high-temperature environments.

Properties

High Hardness:

The tungsten carbide component gives the alloy a high level of hardness (one of the hardest materials known), which is essential for applications involving high wear, such as cutting, grinding, and abrasive environments.

Excellent Wear and Abrasion Resistance:

The wear resistance of WC-Co alloy is outstanding, making it ideal for components that are subject to abrasive wear. Its ability to resist erosion and abrasion is crucial in industries such as mining, oil & gas, and metalworking.