Tungsten Carbide Chromium Carbide Nickel Alloy Nanoparticles

Tungsten Carbide Chromium Carbide Nickel Alloy Nanoparticles

| Tungsten Carbide Chromium Carbide Nickel Alloy Nanoparticles | |

| Product Number | NRE-2056 |

| CAS No. | 12070-12-1/12012-35-0/7440-02-0 |

| Formula | WC-CrC-Ni |

| Molecular Weight | 318.55 / g/mol |

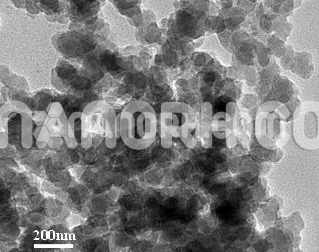

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Tungsten Carbide Chromium Carbide Nickel Alloy Nanoparticles

Applications

Tungsten Carbide Chromium Carbide Nickel (WC-CrC-Ni) alloy nanoparticles represent a highly advanced class of materials that combine the exceptional hardness and wear resistance of tungsten carbide with the corrosion resistance of chromium carbide and the toughness and formability of nickel.

Cutting Tools and Wear-Resistant Materials

Hardness and Wear Resistance: Tungsten carbide (WC) and chromium carbide (CrC) provide outstanding hardness, while nickel (Ni) contributes toughness and ductility. This makes WC-CrC-Ni nanoparticles ideal for manufacturing cutting tools, drill bits, abrasives, and wear-resistant surfaces.

Mining and Drilling Equipment: The hardness of WC-CrC-Ni nanoparticles makes them excellent for use in tools and equipment that operate in high-stress environments, such as mining drills, rock crushers, and other heavy-duty machinery exposed to abrasive wear.

Protective Coatings and Surface Treatments

Hard Coatings for Industrial Components: WC-CrC-Ni nanoparticles can be used to create protective coatings for components exposed to extreme wear and corrosion, such as those in the automotive, aerospace, and industrial sectors. These coatings can significantly enhance the lifespan of parts like turbine blades, engine components, and other high-performance machinery.

Automotive and Aerospace Components

High-Performance Engine Parts: WC-CrC-Ni alloy nanoparticles are utilized in engine parts and other automotive components where durability, resistance to wear, and high-temperature stability are critical. These materials improve the longevity and performance of components like pistons, valves, and exhaust systems.

Aerospace Applications: In aerospace, the alloy nanoparticles can be used in high-performance components such as landing gear, airframe parts, and turbine blades, where their combination of hardness, corrosion resistance, and heat tolerance helps to ensure the longevity and safety of the components under extreme conditions.

Energy Industry Applications

Drilling Tools for Oil and Gas: WC-CrC-Ni nanoparticles are employed in tools used in the extraction of oil and gas, particularly for drilling and cutting through hard rock formations. The wear resistance of tungsten carbide and chromium carbide, combined with the toughness of nickel, makes these nanoparticles suitable for applications in oilfield drilling equipment.