|

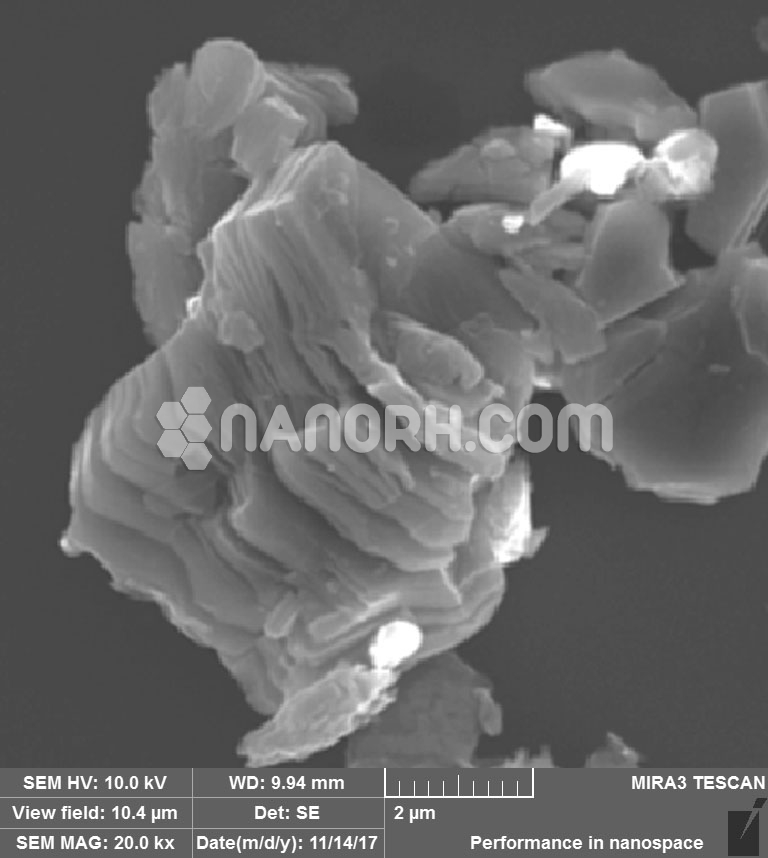

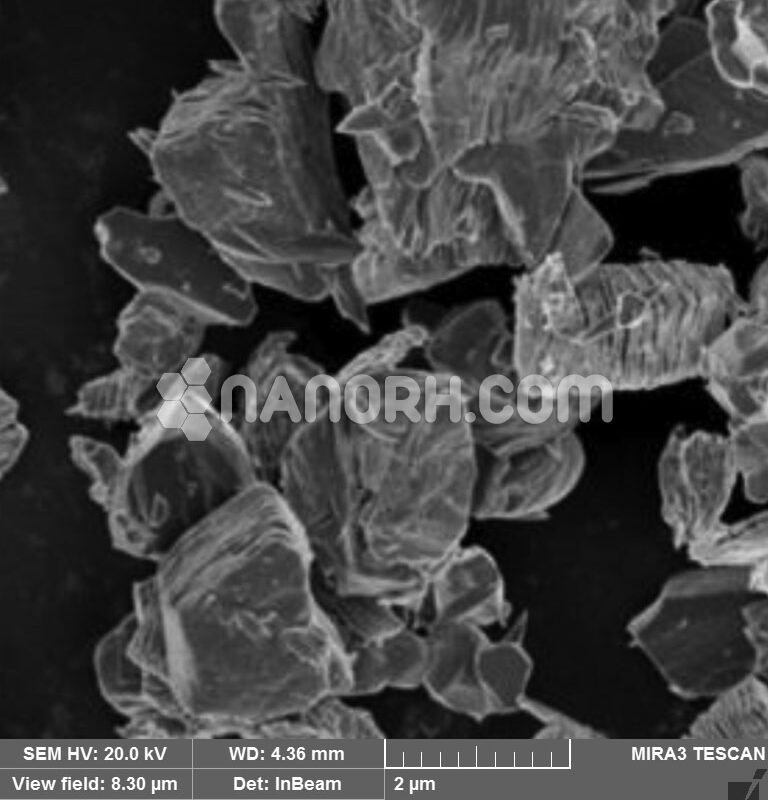

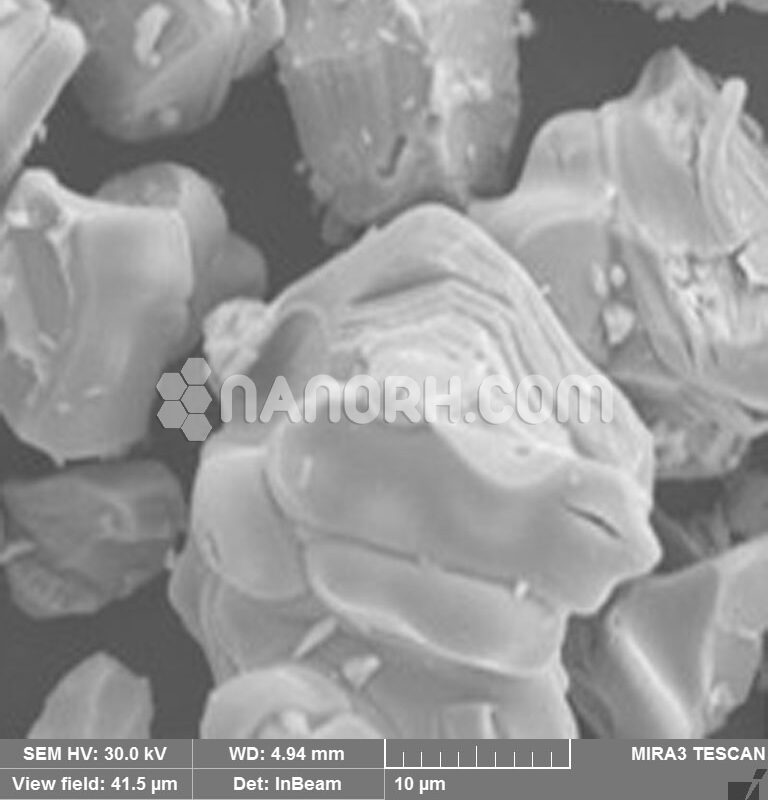

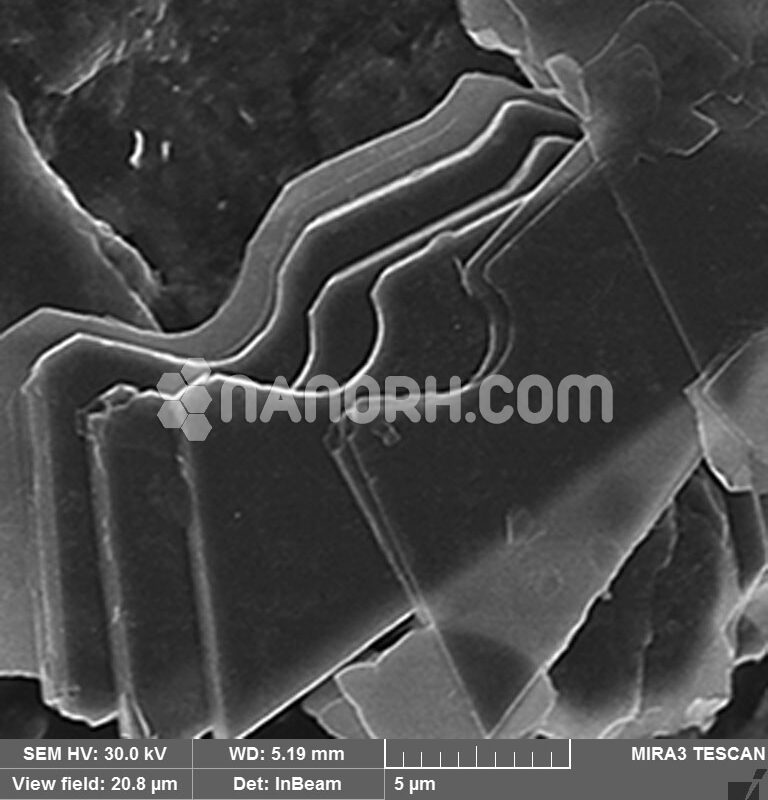

Titanium Tin Carbide MAX Phase Powder |

|

| Product No. | NRE-58015 |

| CAS No. | 12316-56-2 |

| Formula | Ti2SnC |

| Molecular Weight | 226.45 g/mol |

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

|

Certificate of Analysis |

|

| Ti | 42.2% |

| Sn | 52.4% |

| C | 5.3% |

| Al | 0.03% |

| B | 0.02% |

| Cr | 0.01% |

| O | 0.03% |

Titanium Tin Carbide MAX Phase Powder

Titanium Tin Carbide (Ti2SnC) is another member of the MAX phase family, known for its distinctive properties. Like other MAX phases, Ti2SnC combines the best characteristics of ceramics and metals, including high thermal and electrical conductivity, good machinability, and resistance to thermal shock. Here are some potential applications for Titanium Tin Carbide:

High-Temperature Applications: Ti2SnC is stable at elevated temperatures, making it suitable for use in high-temperature environments. This includes components for aerospace, gas turbines, and other applications where materials are exposed to extreme heat.

Wear-Resistant Coatings: Its hardness and resistance to wear make Ti2SnC a good candidate for coatings on tools and machinery that undergo significant friction and wear, such as cutting tools, drilling bits, and industrial machinery parts.

Electronics and Electrical Contacts: Due to its good electrical conductivity, Ti2SnC can be used in electrical contacts, electrodes, and other components where efficient electrical conduction is necessary. It can also be employed in electronic devices that operate under high temperatures.

Thermal Management: The high thermal conductivity of Ti2SnC makes it useful for heat sinks and other thermal management applications. Its ability to conduct heat efficiently can help manage temperatures in electronic devices or other high-power systems.

Nuclear Applications: The stability and robustness of Ti2SnC could be advantageous in nuclear environments, where materials need to withstand radiation and high temperatures. Potential applications include reactor components or other systems in nuclear reactors.

Structural Components: Ti2SnC’s combination of strength, toughness, and thermal stability makes it suitable for use in structural components that must endure high stress and temperature variations, such as in high-performance aerospace structures or heavy-duty industrial machinery.

Cutting and Abrasive Tools: The hardness of Ti2SnC can be utilized in the manufacture of cutting and abrasive tools. These tools benefit from Ti2SnC’s ability to maintain a sharp edge and resist wear over extended use.

In summary, Titanium Tin Carbide’s unique properties allow it to be used in a wide range of high-performance applications, benefiting from its combination of hardness, thermal and electrical conductivity, and stability at high temperatures.