Titanium Tantalum Carbide Tungsten Carbide Alloy Powder

Titanium Tantalum Carbide Tungsten Carbide Alloy Powder

| Ti-TaC-WC Alloy Powder | |

| Product No | NRE-9043 |

| CAS No. | 7440-32-6/12070-06-3/12070-12-1 |

| Formula | Ti-TaC-WC |

| Molecular Weight | 436.6763 g/mol |

| APS | <40 um (Can be Customized) |

| Purity | 99.9% |

| Density | NA |

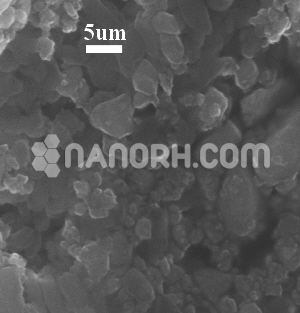

| Color | Gray |

| Melting Point | NA |

| Boiling Point | NA |

Ti-TaC-WC Powder

Ti-TaC-WC Powder is a specialized composite metal powder composed of Titanium (Ti), Tantalum carbide (TaC), and Tungsten carbide (WC). This combination of elements offers a range of enhanced mechanical and physical properties, making it an excellent choice for demanding applications in industries such as aerospace, automotive, mining, and cutting tools.

The individual components of Ti-TaC-WC powder are carefully selected to contribute to the material’s overall performance:

Titanium (Ti): Known for its lightweight and corrosion resistance, titanium provides the composite with excellent strength-to-weight ratio and resistance to oxidation, particularly in high-temperature environments.

Tantalum Carbide (TaC): Tantalum carbide is a highly refractory ceramic compound that provides excellent hardness, thermal stability, and wear resistance. It helps to improve the powder’s ability to withstand high temperatures and extreme mechanical stresses.

Tungsten Carbide (WC): Tungsten carbide is widely recognized for its exceptional hardness, wear resistance, and abrasion resistance. It enhances the composite’s overall durability and performance in environments subject to constant friction and mechanical wear.

Properties of Ti-TaC-WC Powder

High Strength and Hardness:

The combination of tungsten carbide and tantalum carbide imparts exceptional hardness to the Ti-TaC-WC powder, making it highly resistant to wear and abrasion. This property is crucial in applications involving constant friction or high mechanical stresses.

Excellent Wear and Abrasion Resistance:

Both TaC and WC contribute significantly to the wear resistance of the material. The powder is ideal for components that experience repeated mechanical impacts or friction, such as cutting tools and mining equipment.

Thermal Stability:

Ti-TaC-WC powder can withstand extreme temperatures due to the high melting points of both tantalum carbide and tungsten carbide.