| Titanium Diboride Powder | |

| Product No | NRE-11259 |

| CAS No. | 12045-63-5 |

| Formula | TiB2 |

| Density | 4.52 g/cm³ |

| APS | <40µm (Can be Customized) |

| Purity | 99.9% |

| Form | Powder |

| Molecular Weight | 69.489 g/mol |

| Certificate Of Analysis | |

| Ti | 68.8% |

| B | 31.1% |

| C | 0.01% |

| F | 0.03% |

| O | 0.02% |

| Cu | 0.01% |

| Ta | 0.01% |

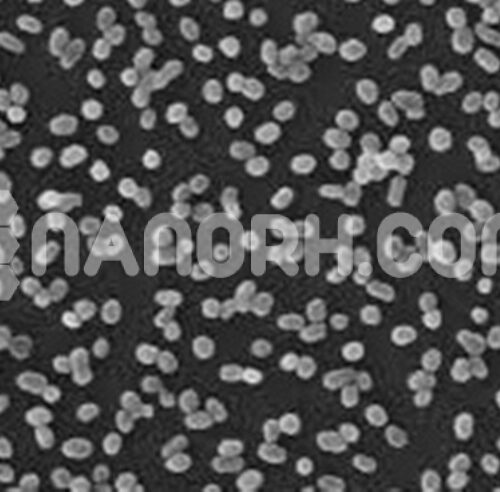

Titanium Diboride Powder

Titanium diboride powder has high melting point, low density, high hardness, good thermal conductivity, high electrical conductivity and remarkable chemical stability. It is one of the candidate materials for structural and high temperature applications. The neutron-absorbing property of boron, along with the aforementioned high-temperature properties, make TiB2 powder the best choice as a control rod material for high-temperature nuclear reactors. TiB2 powder can be prepared by carbothermic reduction of mixed oxides of boron and titanium, reduction of titanium oxide by boron and carbon carbide, reduction of mixed oxides by metals such as aluminum, silicon, magnesium, etc., or synthesized from heating elements. mechano synthesis or self-propagating synthesis at high temperature High temperature and high vacuum favor the formation of TiB2. Since TiB2 powder is very hard and abrasive in nature, the grinding medium and operations should be carefully chosen to avoid contamination during communion, otherwise the grinded powder would need further purification. Despite its useful properties, the application of TiB2 powder is quite limited due to poor sintering. Low diffusivity, exaggerated grain growth at high temperature and the presence of an oxide layer on the surface of the particles are responsible for poor sintering. TiB2 powder can only be thickened at high temperatures, usually by applying pressure during sintering.