Titanium Carbide Tungsten Carbide Alloy Nanoparticles

Titanium Carbide Tungsten Carbide Alloy Nanoparticles

| Titanium Carbide Tungsten Carbide Alloy Nanoparticles | |

| Product Number | NRE-2053 |

| CAS No. | 39377-63-4 |

| Formula | TiC-WC |

| Molecular Weight | 255.72 / g/mol |

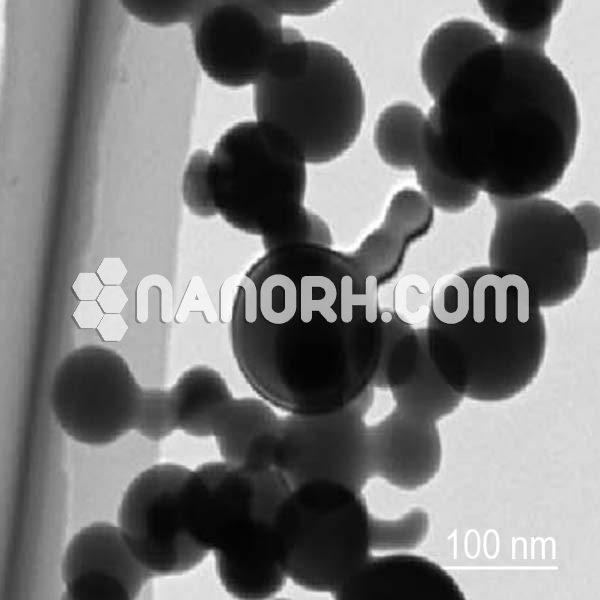

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Titanium Carbide Tungsten Carbide Alloy Nanoparticles

Applications:

Cutting Tools and Wear-Resistant Coatings

Industrial Cutting Tools: Titanium carbide and tungsten carbide are already widely used in cutting tools, such as drills, saw blades, and milling tools. The nanoparticles of TiC-WC alloy offer even better abrasion resistance and cutting performance due to their nanoscale size. These tools are used in industries such as metalworking, mining, and construction, where durability and precision are required.

Wear-Resistant Coatings: The superior hardness and wear resistance of the TiC-WC nanoparticle alloy make it an excellent material for coating machine parts, cutting tools, pumps, and valves. These coatings help extend the lifespan of industrial equipment exposed to high wear, abrasion, and friction.

Aerospace and Automotive Applications

High-Performance Materials: The high thermal stability, strength, and lightweight nature of titanium carbide tungsten carbide alloy nanoparticles make them suitable for use in aerospace and automotive components. They can be used in parts exposed to extreme temperatures and high stress, such as engine components, turbine blades, braking systems, and exhaust systems. Their ability to withstand high pressure and abrasion makes them highly suitable for aerospace applications, particularly in jet engines and spacecraft components.

Enhanced Fuel Efficiency: The use of lightweight yet strong materials in automotive applications can lead to improved fuel efficiency and emissions reductions. TiC-WC alloy nanoparticles help reduce the weight of vehicle components without compromising performance, making them ideal for engine components, brake pads, and clutch systems in high-performance vehicles.

Energy Applications

Energy Storage and Conversion: The high surface area and chemical stability of TiC-WC nanoparticles make them ideal for use in energy storage devices such as supercapacitors and batteries. These nanoparticles can be used as electrode materials to improve the charge-discharge efficiency and capacity of energy storage devices, which are crucial for electric vehicles and renewable energy systems.