Titanium Alloy Powder For 3D Printing

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

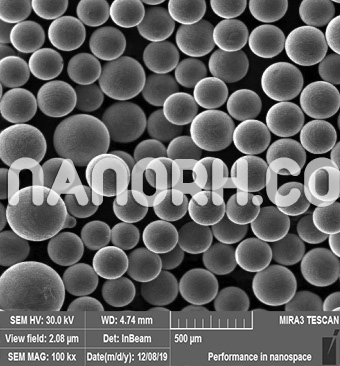

| Product No. | Titanium Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60008 | NRE-Ti6Al4V | Al5.5-6.5, V3.5-4.5, Ti Bal Ti |

0.15max | 3.8-4.8 | 0-15um, 15-45um,45-150um |

| NRE-CPTI | 0.15max | 0-15um, 15-45um,45-150um |

Titanium Alloy Powder For 3D Printing

Applications

Aerospace and Aviation

Engine Components: Titanium alloy powder for 3d printing like Ti-6Al-4V are widely used in the aerospace industry to print components like turbine blades, compressor discs, and exhaust systems. These parts need to withstand extreme temperatures, high pressures, and corrosive conditions.

Airframe Parts: The aerospace industry uses titanium alloy powders to manufacture lightweight yet strong structural components such as brackets, wings, and fuselages. These parts benefit from the material’s high strength-to-weight ratio, improving aircraft fuel efficiency and performance.

Spacecraft Components: 3D printing allows for the creation of complex spacecraft components, such as pressure housings, heat shields, and brackets, with high precision and reduced weight.

Medical and Biomedical Applications

Orthopedic Implants: Titanium alloys are extensively used in 3D printing orthopedic implants, such as hip replacements, knee implants, and spinal fusion devices. The alloy’s strength and biocompatibility make it ideal for producing long-lasting and functional medical implants.

Dental Implants: Titanium alloys, especially Ti-6Al-4V, are widely used in dental implants due to their excellent biocompatibility and resistance to corrosion in the oral environment.

Surgical Instruments: 3D printing with titanium allows the production of high-precision surgical tools, including bone screws, plates, and other instruments used in complex surgeries.

Automotive Industry

Performance Components: Titanium alloys are used in high-performance automotive parts such as exhaust systems, valve springs, and engine components. Their lightweight and high-strength properties make them ideal for applications where weight reduction and thermal stability are crucial.

Custom Automotive Parts: 3D printing allows the production of custom titanium alloy components for automobiles, enabling manufacturers to optimize designs for specific performance needs, including components that are both strong and lightweight.