| Tantalum Niobium Carbide Powder | |

| Product No | NRE-5216 |

| CAS No. | 12070-06-3 |

| Formula | TaNbC |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray Brown |

| Molecular Weight | 285.86 g/mol |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

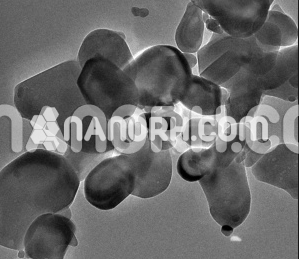

Tantalum Niobium Carbide Powder TaC:NbC=90:10

Introduction

Tantalum Niobium Carbide powder is a refractory ceramic compound composed of tantalum (Ta), niobium (Nb), and carbon (C). It belongs to a class of materials known for their extreme hardness, high melting points, excellent thermal stability, and superior resistance to wear and corrosion. Tantalum and niobium are transition metals with similar properties, making their combination in the form of a carbide particularly attractive for a wide range of high-performance applications, especially in extreme environments.

Properties

Extremely High Melting Point:

Tantalum niobium carbide has an exceptionally high melting point, typically around 3,800 to 4,000°C, making it suitable for high-temperature applications where most other materials would fail. This makes it ideal for environments such as aerospace, nuclear, and cutting-edge manufacturing processes.

Hardness and Wear Resistance:

TaNbC is a hard material, and the combination of tantalum and niobium with carbon in carbide form results in outstanding wear resistance. This hardness makes TaNbC powder ideal for use in abrasive applications, where surfaces and components are exposed to high friction and wear.

Thermal Stability:

The material maintains its properties even at extremely high temperatures, providing exceptional thermal stability. TaNbC powder does not lose its strength, hardness, or resistance to oxidation when exposed to temperatures that can damage other materials. This property makes it suitable for high-performance industrial applications.

Chemical Resistance:

TaNbC exhibits high chemical resistance, particularly in environments that involve aggressive chemicals or extreme conditions. The material is highly resistant to corrosion, oxidation, and acid attack, which makes it valuable in industries where chemical exposure is a concern.