| Spherical Mg-Zn alloy powder | |

| Product No | NRE-60101 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Product | Ratio Mg: Zn | Real density(g/cm³) | Calorific value(J/g) |

|

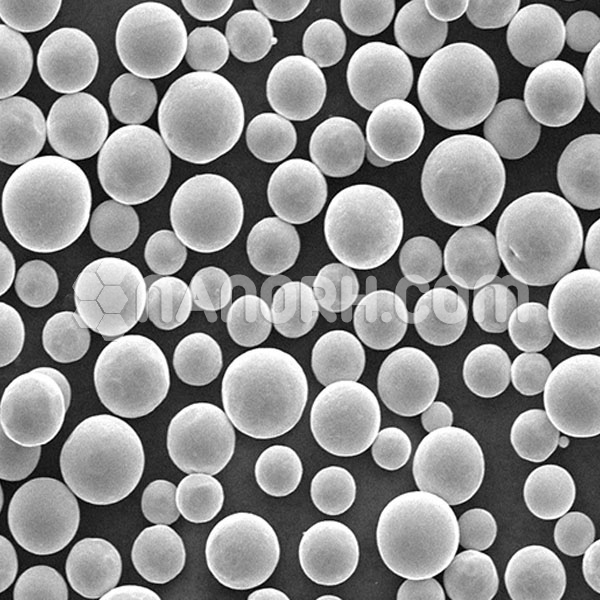

Atomized spherical Mg-Zn alloy powder |

70:30 | 2.26 | 18110 |

| 30:70 | 3.47 | 11180 | |

| 50:50 | 2.83 | 15050 | |

| 20:80 | 4.23 | 9240 | |

| 10:90 | 5.25 | 7300 | |

| 90:10 | 1.92 | 24110 | |

| 95:5 | 1.82 | 24136 |

Spherical Mg-Zn alloy powder

Magnesium alloy is widely used in portable equipment and the automotive industry to achieve the goal of being lightweight.

Mg-Zn alloy atomized powder changed the melting point of zinc powder and the starting point of intense oxidation, completely solved the problems of ignition and stable combustion, and is expected to be widely used in pyrotechnics and in other fields.

Additive Manufacturing (3D Printing):

Spherical Mg-Zn alloy powder is widely used in additive manufacturing, particularly in Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Laser Powder Bed Fusion (LPBF) techniques. These techniques use the powder to create complex, high-performance parts for industries such as aerospace, automotive, and electronics.

Examples of parts include aerospace components, automotive prototypes, and customized structural elements. The high strength-to-weight ratio and corrosion resistance make these alloys ideal for use in critical components exposed to harsh conditions.

Powder Metallurgy (PM):

Mg-Zn alloy powder is used in powder metallurgy to produce automotive parts, structural components, and machine parts. The spherical shape of the powder ensures dense packing and uniform distribution, resulting in components with excellent mechanical properties, wear resistance, and corrosion resistance.

Parts produced through powder metallurgy include brakes, gears, and engine components that require both lightweight and high durability.

Automotive Industry:

Spherical Mg-Zn alloy powder is increasingly used to produce lightweight automotive components such as engine blocks, wheels, brackets, chassis components, and battery housings for electric vehicles (EVs). Magnesium alloys offer a unique combination of low weight and high strength, which helps improve fuel efficiency, battery life, and energy efficiency.

The use of Mg-Zn alloys in the automotive sector also aids in reducing CO2 emissions due to the overall weight reduction of the vehicle.