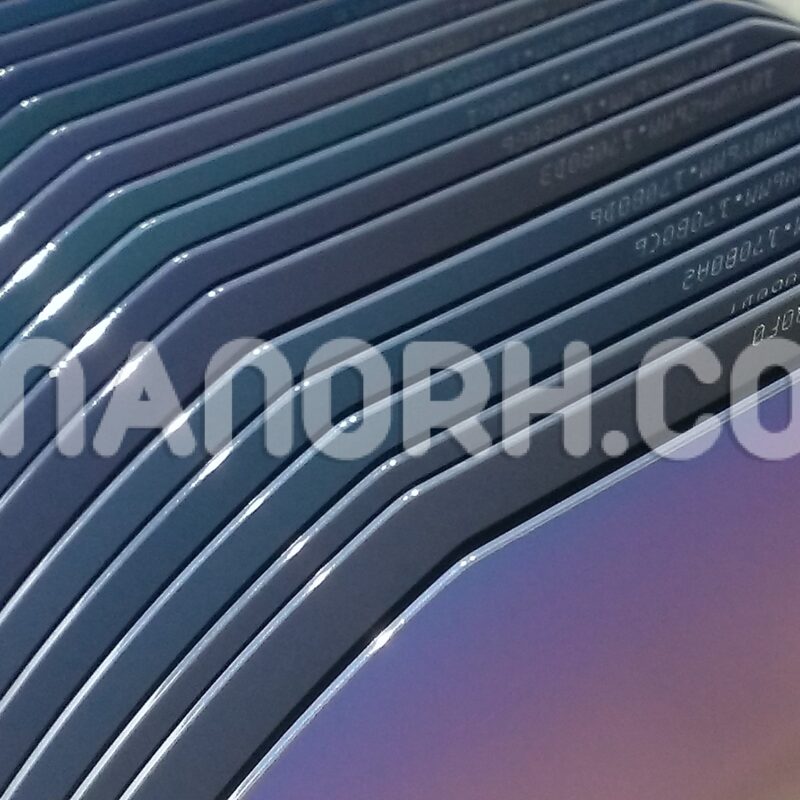

| Silicon Wafer 3 Inch | |

| Product No | NRE-44027 |

| CAS | 7440-21-3 |

| Type | P-Type |

| Crystal method | CZ |

| RRG (%) | ≤12 |

| Oxygen Contents (ppma) | 12.5-16.5 |

| Doping | Boron |

| Diameter (mm) | 3” (76.2mm) |

| Thickness | 250-500μm |

| Resistivity | 1-10ohm-cm |

| Surface | Both Side Polished |

Silicon Wafer 3 Inch

Applications:

Silicon wafer 3 inch are commonly used in the semiconductor industry for various applications. Their size strikes a balance between manufacturing efficiency and cost-effectiveness, making them suitable for different technologies. Here are some key applications:

Integrated Circuits (ICs):

Silicon wafers 3 inch used in the fabrication of microprocessors, memory chips, and logic devices. 3-inch wafers are suitable for prototyping and small-scale production of ICs.

Sensors:

Employed in the production of various sensors, including temperature, pressure, and MEMS (Microelectromechanical Systems) sensors, leveraging silicon’s mechanical and electrical properties.

Photovoltaic Cells:

Used in the manufacture of solar cells, where silicon’s semiconductor properties are harnessed for converting solar energy into electrical energy.

Power Devices:

Suitable for manufacturing power semiconductor devices, including diodes and transistors, which are used in power management and conversion applications.

LEDs and Optoelectronic Devices:

Used as substrates for fabricating light-emitting diodes (LEDs) and other optoelectronic devices, where silicon’s properties can support efficient light generation.

Research and Development:

Commonly used in R&D laboratories for developing new semiconductor materials and devices, where smaller batch sizes are often required.

Surface Acoustic Wave (SAW) Devices:

Utilized in SAW devices for signal processing applications in telecommunications.

Microprocessors:

Suitable for low to mid-range performance microprocessors used in consumer electronics and embedded systems.