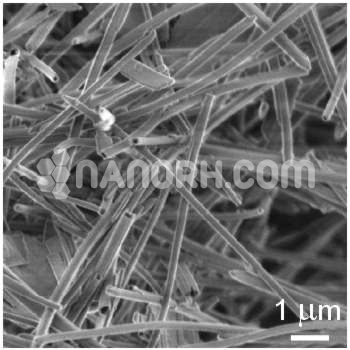

Silicon Nanotubes

Silicon (Si) Nanotubes, Single-Walled, Double Walled and Multi-Walled are tubular ultra high surface area nanotubes. Nanoscale Silicon Nanotubes are typically 10 – 100 nanometers (nm) with specific surface area (SSA) in the 10 – 75 m2/g range.

| Silicon Nanotubes | |

| Product No | NRE-14016 |

| CAS No. | 7440-21-3 |

| Formula | Si |

| Average diameter | 30-50nm |

| Average Length | up to 200µm |

| Purity | 99.9% |

| Molecular Weight | 28.08 g/mol |

| Density | 2330 kg/cm3 |

| Melting Point | NA |

| Boiling Point | 2900 °C |

Silicon (Si) Nanotubes, Single-Walled, Double Walled, and Multi-Walled are tubular ultra-high surface area nanotubes. Nanoscale Si Nanotubes are typically 10 – 100 nanometers (nm) with a specific surface area (SSA) in the 10 – 75 m2/g range. Silicon Nanotubes are also available in coated and dispersed forms. They are also available as a dispersion through the AE Nanofluid production group. Nanofluids are generally defined as suspended nanoparticles in solution either using surfactant or surface charge technology. Nanofluid dispersion and coating selection technical guidance is also available. Other nanostructures include nanorods, nanowhiskers, nanohorns, nanopyramids, and other nanocomposites. Surface functionalized nanoparticles allow for the particles to be preferentially adsorbed at the surface interface using chemically bound polymers.

Application:

Nanocomposites and Materials Engineering

Reinforcement in Composites: SiNTs, due to their high mechanical strength and lightweight nature, are ideal candidates for use in nanocomposites. When integrated into materials like polymers or metals, they can significantly improve the mechanical properties of the composite, such as tensile strength, flexibility, and thermal conductivity. This makes SiNTs useful in the manufacture of lightweight, high-performance materials for applications in aerospace, automotive, and construction industries.

Thermal Conductivity: SiNTs are also used to improve the thermal conductivity of composite materials. In applications that require efficient heat dissipation, such as in electronics and high-power devices, SiNTs can be incorporated to help dissipate heat more effectively.

- Catalysis

Catalytic Support: SiNTs are explored as supports for metal catalysts in reactions such as hydrogenation, dehydrogenation, and CO₂ reduction. The high surface area and the porous structure of SiNTs allow for the effective dispersion of catalysts, improving the efficiency and selectivity of catalytic reactions.

Photocatalysis: SiNTs can also be used in photocatalytic applications for the degradation of pollutants or water splitting to produce hydrogen. Their ability to absorb light and facilitate electron-hole pair generation makes them potential candidates for environmental cleanup and sustainable energy production.

Biomedical Applications

Drug Delivery: Due to their nanoscale size, hollow structure, and biocompatibility, SiNTs have potential as drug delivery carriers. They can encapsulate a variety of therapeutic agents and release them in a controlled manner. Surface functionalization of SiNTs can be used to target specific tissues or cells, enhancing the efficacy of treatments while minimizing side effects.

Biosensing: SiNTs have shown promise as biosensors for detecting biomolecules such as DNA, proteins, and glucose. The electrical conductivity of SiNTs changes upon interaction with these biomolecules, making them highly sensitive and specific for diagnostic purposes.

Imaging: Silicon nanotubes, in combination with other nanomaterials, can serve as contrast agents for medical imaging techniques like magnetic resonance imaging (MRI) or optical imaging. Their ability to interact with light and electromagnetic fields allows for enhanced visualization of tissues or tumors.