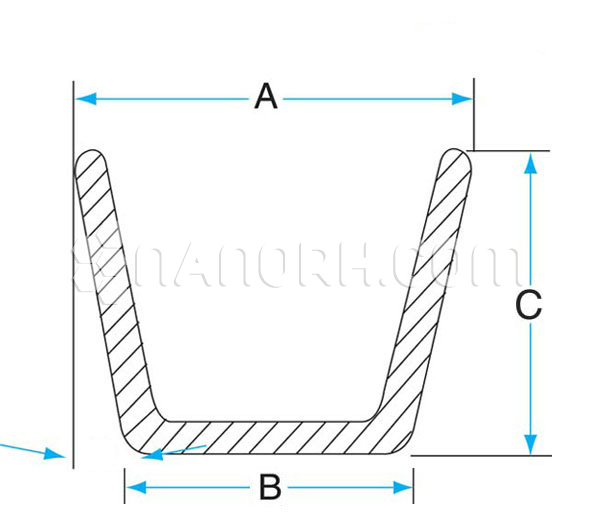

| Silicon Graphite Crucible | |

| Product No | NRE-47007 |

| CAS | NA |

| Purity | >99.9% |

| Apparent Porosity | 14-19 % |

| Capacity | 5ml |

| Cold Bending Strength | 13-20 MPa |

| Hot Bending Strength | 10-15 MPa |

| Density | 2.0-2.2 g/cm³ |

| Melting Point | NA |

| Boiling Point | NA |

Silicon Graphite Crucible

Introduction:

Silicon graphite crucible are specialized containers made from a composite material that combines silicon and graphite. This unique combination offers enhanced properties such as excellent thermal conductivity, high resistance to thermal shock, and improved strength at elevated temperatures. Silicon graphite crucibles are particularly well-suited for applications involving the melting and casting of various metals and alloys.

Applications

Metallurgical Processes:

Melting and Casting: Widely used for melting non-ferrous metals, including aluminum, zinc, and copper alloys. Their thermal properties ensure efficient melting while minimizing oxidation and contamination.

Foundry Work:

Employed in foundries for pouring molten metal. The high thermal conductivity allows for rapid heating and cooling, resulting in better control during the casting process.

Sintering:

Used in the sintering of ceramics and composite materials. The crucibles facilitate uniform heating, which is crucial for achieving desired material properties.

High-Temperature Research:

Utilized in laboratories for high-temperature experiments and materials testing, especially in materials science and metallurgy, where precise thermal control is essential.

Glass and Ceramics Production:

Applied in the production of glass and ceramics, providing a stable environment for melting raw materials while resisting chemical reactions.

Solar Cell Manufacturing:

Used in the photovoltaic industry for melting silicon and producing solar cells, where high purity and thermal stability are critical.

Chemical Processing:

Employed in chemical reactions that require resistance to corrosive materials, ensuring the integrity of both the crucible and the product.

Electronics Manufacturing:

Utilized in the semiconductor industry for processes that involve high temperatures, such as the deposition of thin films and crystal growth.

Thermal Treatment:

Applied in heat treatment processes for various metals, helping to achieve specific mechanical properties through controlled heating.

Reviews

There are no reviews yet.