| Silicon Carbide Whiskers | |

| Product No | NRE-5197 |

| CAS No. | 409-21-2 |

| Formula | SiC |

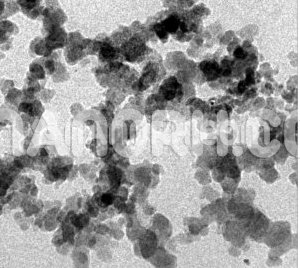

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | bluish-black |

| Molecular Weight | 40.0962 g/mol |

| Density | 3.16 g/cm³ |

| Melting Point | 2830°C |

| Boiling Point | NA |

Silicon Carbide Whiskers

Silicon Carbide Whisker as reinforcement material was obtained by mixing and sintering silicon carbide fibers and alumina powder. SiC Whisker exhibits a higher modulus of elasticity, strength, and hardness than many other whiskers, as well as having better chemical stability.

Reinforcement of Composites

One of the primary applications of SiC whiskers is in reinforcing composite materials. SiC whiskers are added to metals, polymers, and ceramics to enhance their mechanical properties.

Ceramic Composites: SiC whiskers are commonly used as a reinforcement in ceramic matrices, such as alumina and zirconia, to improve their toughness and resistance to thermal shock. These composites are widely used in high-performance applications like gas turbines, rocket nozzles, and brake discs, where both strength and resistance to wear and high temperatures are crucial.

Polymer Composites: SiC whiskers are also used to reinforce polymer matrices, improving the mechanical properties of the resulting composite materials. This is particularly useful in automotive and aerospace industries for manufacturing lightweight, durable components.

Metal Matrix Composites: In metal matrix composites, SiC whiskers improve the strength, stiffness, and wear resistance of metals like aluminum, magnesium, and titanium alloys. These SiC-enhanced materials are employed in high-stress environments, such as engine components, braking systems, and structural parts in the aerospace and automotive industries.

Abrasives and Cutting Tools

Due to their high hardness, SiC whiskers are used in the production of abrasive materials and cutting tools. These whiskers can be incorporated into abrasive discs, grinding wheels, and cutting tools to increase the material’s hardness, wear resistance, and overall performance.

Grinding Wheels: The high-strength SiC whiskers enhance the efficiency and longevity of grinding wheels. They improve the precision of cutting and grinding operations, making them ideal for processing hard materials like metals, ceramics, and stones.

Cutting Tools: SiC whiskers can be used in the manufacturing of cutting tools, such as drills, lathe tools, and saw blades, providing excellent wear resistance, high-temperature stability, and cutting efficiency.