| Silicon Carbide Powder | |

| Product No | NRE-5197 |

| CAS No. | 409-21-2 |

| Formula | SiC |

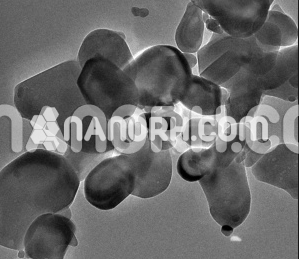

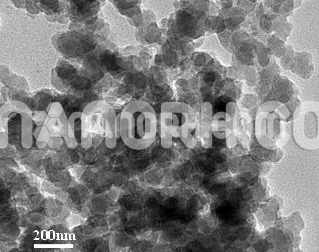

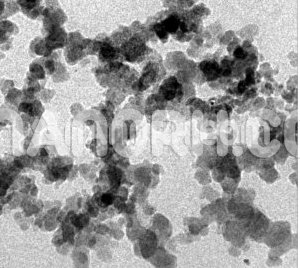

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | bluish-black |

| Molecular Weight | 40.0962 g/mol |

| Density | 3.16 g/cm³ |

| Melting Point | 2830°C |

| Boiling Point | NA |

Silicon Carbide Powder

SiC powder is by far the most widely used oxide-free ceramic for many industrial applications due to its attractive high temperature properties, such as high strength, high hardness and high resistance to wear and thermal shock. It also has excellent resistance to chemical oxidation. Carbothermal reduction of sand by coke, known as the Acheson process, is the main method of producing SiC powder. However, this method is an energy-intensive process and involves many steps in the synthesis of a pure SiC powder. In addition, the particle size of the powder is relatively coarse and requires grinding, and therefore it is difficult to sinter. This process has been modified to produce fine, pure Silicon carbide powder, and the modified process is called rapid carbothermic reduction (RCR). The original RCR process showed that the reaction between silica and carbon to form SiC can be achieved within seconds when heat transfer resistances are removed. Synthesis of silicon carbide using the RCR process revealed that once SiC is formed on the surface of primary carbon particles, the primary particles begin to grow by sintering during high temperature processing, causing further densification. becomes difficult. Over the past decade, several researchers have made efforts to synthesize fine and pure Silicon carbide powder by alternative methods such as sol-gel, plasma, and laser.