| Silicon Carbide Crucibles | |

| Product No | NRE-47006 |

| CAS | 409-21-2 |

| Purity | >99.9% |

| Thermal Conductivity | 45W/m*k |

| Capacity | 5ml |

| Bending Strength | 280 MPa |

| Ash | 3 % |

| Rigidity | 13 |

| Melting Point | 2730 °C |

| Boiling Point | NA |

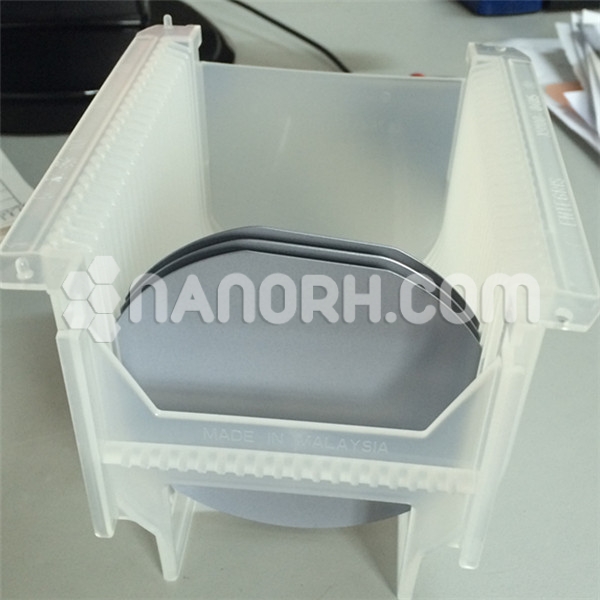

Silicon Carbide Crucibles

Introduction:

Silicon carbide crucibles are high-performance containers made from silicon carbide, a compound known for its exceptional hardness, thermal conductivity, and chemical resistance. These crucibles can withstand extreme temperatures and thermal shock, making them ideal for various demanding applications in industries that require high durability and thermal stability.

Applications

Metallurgical Processes:

Melting and Casting: Used for melting non-ferrous metals and alloys, including aluminum and zinc, due to their ability to handle high temperatures without deforming or reacting with the molten metal.

Sintering:

Employed in the sintering of ceramics and advanced materials, providing a stable and uniform heating environment that ensures high-quality material properties.

High-Temperature Research:

Utilized in laboratories for high-temperature experiments, particularly in materials science, where precise thermal management is essential.

Glass Production:

Used in the glass industry for melting raw materials, benefiting from their resistance to thermal shock and chemical stability.

Chemical Processing:

Applied in processes that involve reactive and corrosive substances, as silicon carbide’s inert nature prevents contamination and degradation.

Semiconductor Manufacturing:

Employed in the production of silicon carbide wafers and other semiconductor materials, where high thermal conductivity and stability are crucial.

Furnace Linings:

Used as linings in high-temperature furnaces and kilns, leveraging their ability to withstand extreme conditions while maintaining structural integrity.

Refractory Applications:

Utilized in various refractory applications where resistance to high temperatures and corrosive environments is necessary.

Reviews

There are no reviews yet.