| Saponite Clay Nanoparticles | |

| Product No | NRE-6028 |

| CAS No. | 1319-41-1 |

| Formula | NA |

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | White/yellow/greenish |

| Molecular Weight | 480.19 g/mol |

| Density | 2.3 g/cm3 |

| Melting Point | NA |

| Boiling Point | NA |

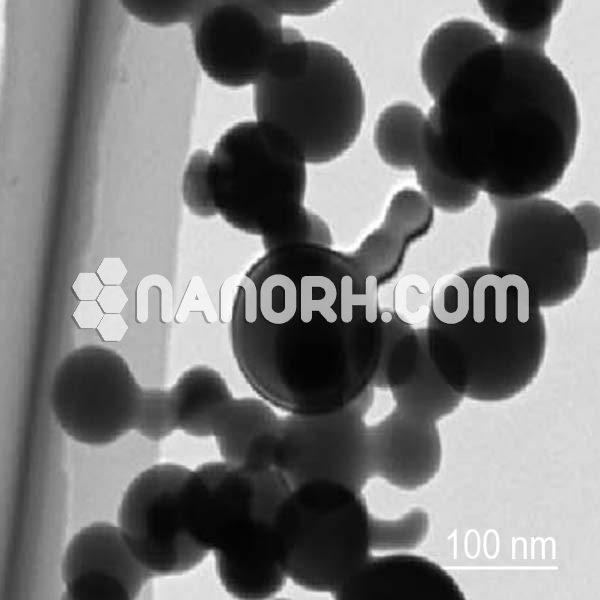

Saponite Clay Nanoparticles

This nanoparticles have high specific surface area (SSA), surface acidity and cation exchange capacity (CEC). Moreover, it is distinguished from dioctahedral smectites such as montmorillonite (Mt) and nontronite. The particle size of Sap (~50 nm) is generally smaller than that of Monte (~300 nm). Additionally, saponite is easier to delaminate and exfoliate into nanoplatelets or even individual nanolayers in water. However, the natural sap is rare. Due to the presence of impurities in sap deposits in nature, laborious and slow purification is required to obtain a relatively pure saponite. Moreover, the chemical composition of the natural sap can be extremely variable, depending on the process of geological genesis. This defect limits the use of Saponite clay nanoparticles in catalysis, adsorption and optics. Therefore, lymph-like solids with a well-controlled chemical composition are synthesized, and these solids are often referred to as synthetic sap. In general, the typical approach for SAP synthesis is hydrothermal synthesis. The process can be modified to be microwave assisted synthesis and sol-gel synthesis. Sap synthesis is relatively mature, at least on a laboratory scale. However, natural and synthetic sap is rarely used directly. In many circumstances, the sap needs modifications, including surface engineering, intercalation, and sap hybridization. Many types of Sap-based hybrids or compounds have been successfully prepared by intercalating bulky organic and inorganic cationic species, neutral polar molecules, and polymers into the Sap interlayer space. The covalent grafting of a part of the organic molecules on the surface of the sap proves to be feasible. As a result, the resulting saponite materials have been tested for a wide range of applications. More and more studies show that such materials can be used as adsorbents.