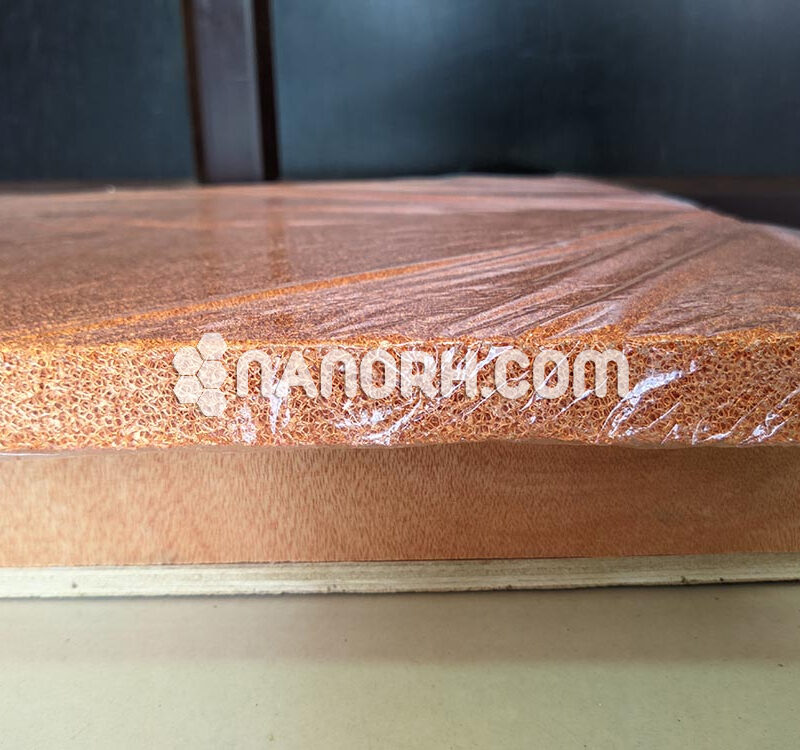

Reticulated Vitreous Carbon Foam (Purity: 99.9%, Thickness: 5mm)

| Reticulated Vitreous Carbon Foam | |

| Product No | NRE-51016 |

| CAS | 7440-44-0 |

| Thickness | 5mm |

| Compression Strength | 15-75 psi |

| Purity | 99.9% |

| Shear Strength | 4.4×103 psi |

| Tensile Strength | 25-50 psi |

| Temperature In air | 600°F |

| Bulk Thermal Conductivity | 0.021-0.29 BTU/ft •hr•°F |

| Coefficient of Thermal Expansion | 1.2 × 10-6 in/in°F (0-100°C) |

| Bulk Resistivity | 12.7 × 10-2 ohm • in |

Reticulated Vitreous Carbon Foam

Reticulated vitreous carbon (RVC) foam is a unique, highly porous material composed of pure carbon with a glassy, vitreous structure. Its open-cell structure, chemical inertness, and high thermal stability make it valuable in a variety of advanced applications. Here are some key applications of reticulated vitreous carbon foam:

Electrochemical Applications

Electrodes in Batteries: RVC foam is used as an electrode material in various types of batteries, including lithium-ion and sodium-ion batteries. Its high surface area and conductive properties enhance the efficiency of charge storage and facilitate faster charge-discharge cycles.

Supercapacitors: In supercapacitors, RVC foam serves as a conductive scaffold that maximizes the electrode’s surface area, improving energy storage capacity and power delivery.

Fuel Cells: RVC foam is used as an electrode or catalyst support in fuel cells. Its porous structure provides ample surface area for electrochemical reactions, improving the overall efficiency of the cell.

Filtration and Separation

High-Temperature Filtration: Due to its thermal stability and chemical inertness, RVC foam is used in filtration systems for high-temperature gases and corrosive environments. It can effectively filter particulates without degrading under extreme conditions.

Electrochemical Filtration: RVC foam can be used in filtration processes where electrochemical reactions are involved, such as in water treatment or chemical synthesis, to remove impurities while also acting as an electrode.

Catalysis

Catalyst Supports: RVC foam’s high surface area and chemical stability make it an ideal support material for catalysts in various chemical reactions, including oxidation, reduction, and hydrogenation. It enhances the dispersion of the catalyst, increasing reaction efficiency.

Hydrogen Production: In hydrogen production processes, such as water electrolysis, RVC foam is used as a catalyst support to enhance the efficiency of hydrogen generation.

Biomedical Applications

Scaffolds for Tissue Engineering: RVC foam’s porous structure is being explored for use in biomedical applications, particularly as scaffolds for tissue engineering. Its biocompatibility and ability to support cell growth make it suitable for developing bone and cartilage tissues.

Drug Delivery Systems: RVC foam’s high surface area and customizable porosity allow for its use in controlled drug delivery systems, where it can be used to gradually release therapeutic agents.