| Polyetherketoneketone | |

| Product No | NRE-54016 |

| CAS | 29658-26-2 |

| Purity | 99.9% |

| Formula | PEKK |

| Density | 1.32 G/cm³ |

| Colour | White |

| APS | NA |

| Tensile elongation | 3000% |

| Tensile strength | 110 MPa |

| Melting Point | 310-360 °C |

| Boiling Point | NA |

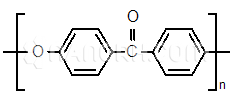

Polyetherketoneketone (PEKK)

Polyetherketoneketone (PEKK) is a member of the polyaryletherketone (PAEK) family of thermoplastics, known for its exceptional mechanical properties, chemical resistance, and thermal stability. PEKK has similar properties to Polyetheretherketone (PEEK) but offers certain advantages in specific applications, particularly where even higher performance is required.

Aerospace Industry

Structural Components: Polyetherketoneketone (PEKK) is used in aircraft structural components, such as brackets, clips, and fasteners, where lightweight materials with high strength and thermal stability are essential.

Engine Components: Polyetherketoneketone high-temperature resistance makes it suitable for engine components that must endure extreme conditions.

Composites: Polyetherketoneketone is often used in composite materials for aircraft, providing enhanced strength-to-weight ratios and resistance to chemicals and fire.

Defense and Military

Ammunition Casings: is used in the manufacture of lightweight, durable ammunition casings that can withstand high temperatures and pressures.

Ballistic Protection: Due to its strength and impact resistance, is employed in ballistic protection materials for personal armor and vehicle protection.

Automotive Industry

High-Performance Components: is used in high-performance automotive components such as gears, bearings, and electrical connectors, particularly in applications requiring high thermal stability and wear resistance.

Hybrid and Electric Vehicles: In electric vehicles, is used for parts that require both electrical insulation and high mechanical strength.

Oil and Gas Industry

Downhole Components: is suitable for use in downhole components like seals, connectors, and valve seats, which must resist high temperatures, pressures, and chemical exposure.

Pipes and Linings: is also used in pipes and linings that are exposed to harsh chemicals and need to maintain integrity under extreme conditions.

Medical Industry

Implants: Similar to is biocompatible and used in medical implants, including spinal cages, dental implants, and joint replacements. Its ability to be sterilized and its resistance to wear make it ideal for long-term medical applications.

Surgical Instruments: is employed in surgical instruments that must be sterilized repeatedly and retain their mechanical properties over time.

Electronics and Semiconductor Industry

High-Performance Insulators: is used in electronic components that require high dielectric strength, thermal stability, and resistance to chemicals.

Semiconductor Manufacturing Equipment: chemical resistance makes it suitable for components in semiconductor manufacturing equipment, where it can withstand aggressive cleaning chemicals and high temperatures.