| Niobium Carbide Powder | |

| Product No | NRE-5177 |

| CAS No. | 12069-94-2 |

| Formula | NbC |

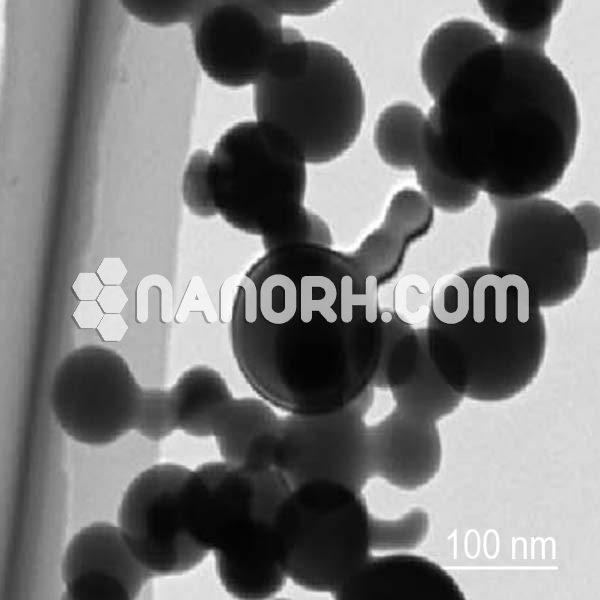

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Gray Brown |

| Molecular Weight | 104.91708 g/mol |

| Density | 7.82 g/cm3 |

| Melting Point | 3,490°C |

| Boiling Point | 4,300 °C |

Niobium Carbide Powder

Introduction

Niobium carbide powder is a refractory ceramic compound made of niobium and carbon. This material is notable for its exceptional hardness, high melting point, and resistance to wear and corrosion. Niobium carbide powder, as a fine, nanoscale material, possesses these properties in an enhanced form due to the small particle size, which provides a larger surface area for reactions and applications.

Applications

Wear-Resistant Coatings

Niobium carbide powder is often incorporated into coatings to enhance the wear resistance of tools and machine parts. Due to its hardness and stability, NbC coatings are used in:

Cutting tools: High-performance cutting tools such as drill bits, milling tools, and saw blades benefit from NbC coatings to withstand abrasion and high temperatures.

Mining and excavation equipment: Tools used in mining operations, such as drill bits and shovels, are coated with NbC to improve durability.

Mechanical parts: Components exposed to wear and friction in industries like automotive, aerospace, and manufacturing are coated with NbC to extend their life and performance.

Composite Materials

Niobium carbide powder is often used as a reinforcement phase in composite materials. By adding NbC powder to metal, ceramic, or polymer matrices, these materials gain improved mechanical properties:

Metal Matrix Composites (MMC): NbC is used in combination with metals such as titanium, aluminum, and steel to create composites with enhanced strength, hardness, and thermal stability.

Ceramic Matrix Composites (CMC): NbC can be added to ceramics to enhance their mechanical properties, especially at high temperatures, for use in demanding environments like aerospace.

Polymer Composites: Incorporating NbC into polymers results in composite materials with improved wear resistance, making them ideal for high-stress applications.

Cutting and Abrasive Materials

Due to its extreme hardness, niobium carbide powder is a key component in the manufacture of cutting tools, abrasives, and grinding wheels. These materials are used in:

Diamond tools: NbC is used in the production of advanced diamond-coated tools for machining hard materials.

Abrasive powders: As a fine abrasive, NbC is used in polishing, grinding, and cutting applications, particularly for hard metals and ceramics.