| Nickel Tungsten Alloy Sputtering Target | |

| Product No | NRE-43122 |

| CAS No. | 51890-28-9 |

| Formula | NiW |

| Molecular Weight | 241.88 |

| Purity | 3N, 3N5 |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Electrical Resistivity | NA |

| Electronegativity | NA |

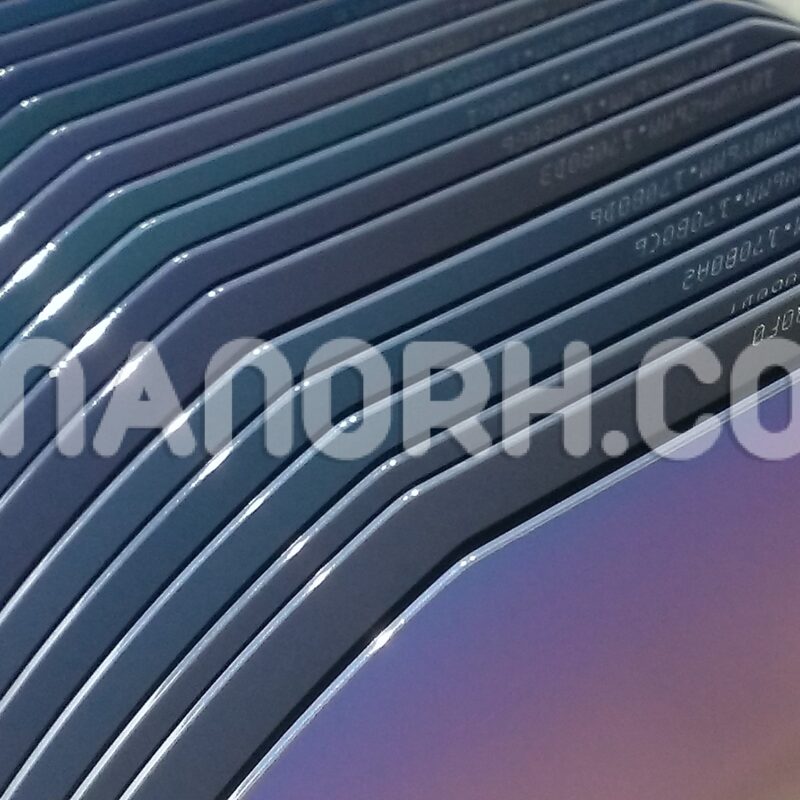

Nickel Tungsten Alloy Sputtering Target

Introduction

Nickel tungsten alloy sputtering target are composite materials that combine nickel (Ni) and tungsten (W) to leverage the beneficial properties of both metals. Nickel provides good corrosion resistance and ductility, while tungsten contributes to high strength, hardness, and thermal stability. This combination results in an alloy that is valuable in various demanding applications, particularly in electronics, aerospace, and high-temperature environments.

Applications

Electronics: Nickel tungsten alloy are used in the fabrication of thin films for electronic components, such as resistors and capacitors. Their electrical conductivity and thermal stability make them suitable for high-performance electronic applications.

Hard Coatings: The hardness and wear resistance of nickel tungsten alloy make them ideal for protective coatings. These coatings can enhance the durability of tools and components in industrial applications, reducing wear and extending lifespan.

Aerospace Components: The high strength and thermal resistance of nickel tungsten alloy make them suitable for aerospace applications, including engine components and structural parts that require reliability under extreme conditions.

Medical Devices: In the medical field, nickel tungsten alloy can be used for surgical instruments and implants. Their corrosion resistance and mechanical properties are advantageous for applications within the human body.

Chemical Processing: Nickel tungsten alloy are often employed in environments where resistance to corrosion and high temperatures is required, making them suitable for equipment used in chemical processing and petrochemical industries.

Additive Manufacturing: Nickel tungsten alloy can be utilized in additive manufacturing processes (3D printing) for producing high-performance components that benefit from their unique mechanical properties.

Surface Treatments: Sputtering targets made from nickel tungsten alloy are used to create thin films in surface treatment applications, providing enhanced wear resistance and protection against corrosion.