| Nickel Titanium Alloy Nanopowder | |

| Product No | NRE-2037 |

| CAS No. | 7440-02-0/7440-32-6 |

| Formula | Ni-Ti |

| Density | 6.45 g/cm3 |

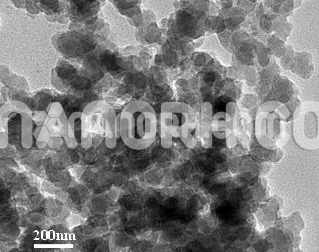

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Melting Point | 1310°C |

| Boiling Point | NA |

| Molecular Weight | 106.56 g/mol |

Nickel Titanium Alloy Nanopowder

Applications

Biomedical Applications

Medical Implants and Stents: NiTi alloys have long been used in the medical field due to their biocompatibility, flexibility, and shape memory. When processed into nanopowder, the material can be used in the creation of implants, such as stents or bone scaffolds, which can adapt to changes in the body’s environment. NiTi alloy nanopowder can be fabricated into devices that expand or contract based on temperature, ensuring better functionality and fit when inserted into the body.

Orthopedic Devices: In addition to stents, NiTi nanopowder is used in orthopedic implants like screws, plates, and wires, which can help treat fractures and spinal conditions. The ability to adapt to body temperature and mechanical stress, as well as the material’s ability to “remember” a shape, ensures better integration with biological tissues.

Robotics and Actuators

Robotic Actuators: The shape memory effect of NiTi alloys makes them ideal for use in actuators in robotics, especially for small, flexible robots or soft robotics. NiTi alloy nanopowders are being investigated for the development of actuators that use temperature-induced shape changes to perform tasks such as gripping, moving, or lifting. These actuators are valuable for applications requiring precision, flexibility, and adaptability, such as in medical robots or micro-robots.

Artificial Muscles: The ability of NiTi nanopowders to undergo reversible deformation makes them a candidate material for creating artificial muscles in robotics. These muscles can mimic the performance of natural biological muscles, providing actuation without the need for bulky motors or electrical systems.

Aerospace and Automotive Industries

Shape-Morphing Components: In the aerospace and automotive sectors, NiTi alloy nanopowders are being studied for use in morphing components. For example, the alloys can be used in aircraft wings or vehicle body parts that change shape in response to external stimuli such as airflow or temperature. This technology can improve fuel efficiency, aerodynamics, and overall performance by allowing components to adapt dynamically to their environment.

Energy Systems

Energy Harvesting: NiTi alloys, including nanopowders, are also being researched for energy harvesting applications. These materials can convert mechanical energy (from vibrations or motion) into electrical energy by exploiting their superelasticity or shape memory effect. In energy systems where small-scale, sustainable energy generation is required, such as in wearable electronics or remote sensors, NiTi alloy nanopowders could play a significant role.