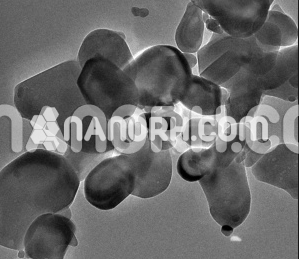

Nickel Graphite Alloy Nanoparticles

| Nickel Graphite Alloy Nanoparticles | |

| Product Number | NRE-2036 |

| CAS No. | 7440-02-0/ 7440-44-0 |

| Formula | Ni-C |

| Molecular Weight | 70.704 g/mol |

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

Nickel Graphite Alloy Nanoparticles

Applications

Tribological Applications (Lubrication and Wear Resistance): One of the most prominent applications of Nickel-Graphite alloy nanoparticles is in tribology—the study of friction, wear, and lubrication. The addition of graphite as a solid lubricant significantly reduces friction between surfaces in motion. This makes these nanoparticles ideal for use in automotive components, such as bearings, pistons, and gears, as well as in machinery parts that undergo constant wear.

Electrical and Electronics Applications: Nickel-Graphite alloys are also widely used in electrical and electronic applications, where their good electrical conductivity is crucial. These alloys are particularly valuable in the development of components like electrodes, capacitors, and conductive coatings. In applications where high conductivity and low wear are required—such as in batteries, fuel cells, and circuit boards—Nickel-Graphite alloy nanoparticles provide a balance of both performance and durability.

Heat Exchange and Thermal Management: The high thermal conductivity of both nickel and graphite makes the Nickel-Graphite alloy nanoparticles suitable for use in heat exchangers, cooling systems, and thermal management applications. The nanoparticles can be used in systems that require the efficient dissipation of heat, such as in electronics, engines, and power plants. Their ability to withstand high temperatures and maintain stability under thermal stress makes them invaluable in industries where heat is a significant concern.

Aerospace and Automotive Components: Due to their high strength, wear resistance, and corrosion resistance, are ideal for aerospace and automotive applications. In engines, turbines, and other high-performance components, these nanoparticles can significantly reduce the risk of material degradation caused by heat, friction, and corrosion. They can be used in the manufacture of lightweight, durable components that operate in extreme conditions.

Battery and Energy Storage Systems: Nickel-Graphite alloys are commonly used in rechargeable batteries, especially in applications that require high power density and long cycle life. The combination of nickel’s strength and graphite’s conductivity makes these nanoparticles useful in electrodes for batteries and supercapacitors.