Nickel Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

Nickel Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

| Nickel Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles | |

| Product No | NRE- 2035 |

| CAS No. | NA |

| Formula | NiCoCrAlY |

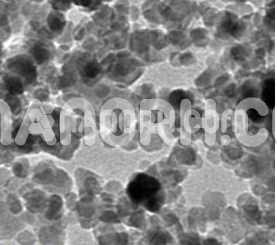

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 285.51 g/mol |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

Nickel Cobalt Chromium Aluminium Yttrium Alloy Nanoparticles

Introduction

The development and utilization of nanoparticles have become crucial to advancing technologies across many fields, including materials science, energy, electronics, and catalysis. Nanoparticles, defined as particles with at least one dimension in the range of 1 to 100 nanometers, exhibit unique properties that are vastly different from bulk materials. Among the most promising materials being explored are alloy nanoparticles, which are made by combining two or more metals.

The Significance of Alloy Nanoparticles

Nanoparticles often exhibit a combination of enhanced physical, chemical, and mechanical properties due to their high surface area, small size, and unique atomic structure. These properties can be drastically different from those of the bulk material. For instance, nanoparticles of metals may have increased catalytic activity, improved strength, or better resistance to wear and corrosion compared to their larger counterparts. By synthesizing nanoparticles from alloy compositions, scientists can take advantage of the distinct properties of multiple metals, creating materials with specific characteristics that meet the requirements of demanding applications.

Composition and Properties

Nickel (Ni): Nickel is a versatile metal widely known for its excellent resistance to corrosion, particularly in oxidizing environments. It also imparts good mechanical properties, thermal stability, and magnetic characteristics. Nickel-based alloys are commonly used in industrial applications, including in turbines, aerospace components, and other high-performance systems.

Cobalt (Co): Cobalt contributes to the alloy’s strength, high-temperature stability, and wear resistance. It is also known for improving the hardness of the alloy, which is essential in applications requiring durability under extreme stress. Cobalt enhances the alloy’s magnetic properties, which may be important for certain electronic or sensor-based applications.

Chromium (Cr): Chromium is primarily added to improve the alloy’s resistance to oxidation and corrosion. It helps form a protective oxide layer on the surface of the material, thereby increasing its longevity in harsh conditions. Chromium also enhances the alloy’s hardness and resistance to wear.