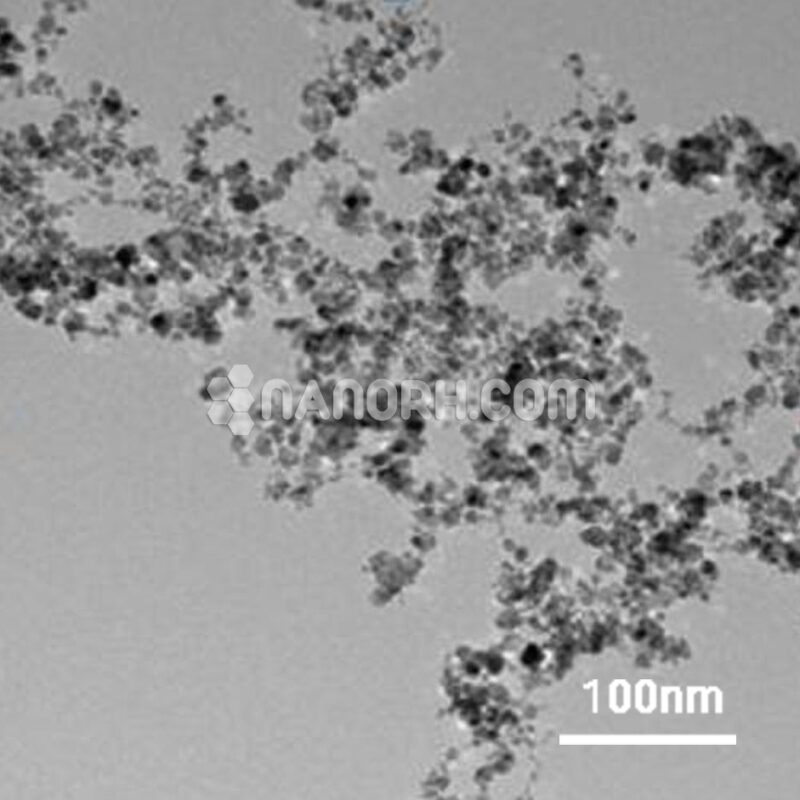

Nickel Cobalt Chromium Aluminium Alloy Powder

| Nickel Cobalt Chromium Aluminium Alloy Powder | |

| Product Number | NRE-9083 |

| CAS No. | NA |

| Formula | NiCoCrAl |

| Molecular Weight | 196.60 g/mol |

| APS | <40 µm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | NA |

| Melting Point | NA |

| Boiling Point | NA |

| Certificate of Analysis | |

| Ni | 29.8% |

| Co | 29.9% |

| Cr | 26.4% |

| Al | 13.8% |

| Fe | 0.02% |

| Mg | 0.04% |

Nickel Cobalt Chromium Aluminium Alloy Powder

Applications

Aerospace and Aviation:

One of the primary applications of Ni-Co-Cr-Al alloy powder is in the aerospace industry, where it is used for producing turbine blades, nozzles, combustion chambers, and engine components. These components operate under extreme temperatures and mechanical stresses, and the alloy’s high strength, oxidation resistance, and thermal stability ensure reliable performance in jet engines and gas turbines.

Gas Turbines and Power Generation:

Ni-Co-Cr-Al alloys are widely used in gas turbines and power generation applications due to their ability to withstand high-temperature conditions. The alloy is used in critical components such as rotor blades, discs, buckets, and bore seals where oxidation resistance, creep resistance, and mechanical strength are essential for long-term durability.

Thermal Spraying and Coatings:

Ni-Co-Cr-Al alloy powder is commonly used in thermal spraying processes, such as plasma spraying, flame spraying, and high-velocity oxy-fuel (HVOF) spraying, to produce protective coatings on components exposed to wear, abrasion, and oxidation. These coatings are used in a variety of industries, including aerospace, automotive, marine, and chemical processing to protect critical components from harsh operating conditions.

Additive Manufacturing (3D Printing):

Ni-Co-Cr-Al alloy powder is increasingly being used in additive manufacturing processes like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS). These techniques allow for the production of complex high-performance components such as turbine blades, engine parts, and heat exchangers with optimized geometries, especially in the aerospace and energy generation sectors.

Automotive Industry:

In the automotive industry, Ni-Co-Cr-Al alloys are used for engine parts, exhaust systems, turbochargers, and valves that need to withstand high temperatures and corrosive environments. The alloy’s oxidation resistance and thermal stability make it ideal for components exposed to exhaust gases, hot engine parts, and high-stress conditions.