| Nickel Chromium Canes | |

| Product No | NRE-62034 |

| CAS No. | 11106-97-1 |

| Formula | Ni/Cr 80/20 wt % |

| Size | 490mg–510mg (Can be Customized) |

| Quantity | 100g, 500g |

| Purity | 99.99% |

| Molecular Weight | 110.68 g/mol |

| Density | Na |

| Melting Point | Na |

| Boiling Point | Na |

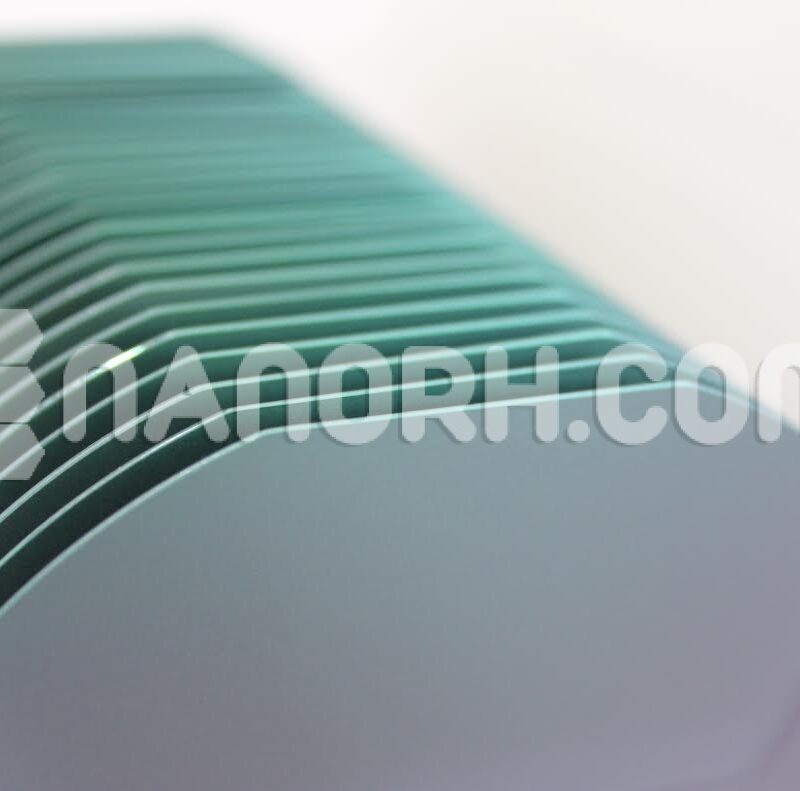

Nickel Chromium Canes

Introduction;

Nickel chromium canes are metal components made from an alloy of nickel and chromium, known for their excellent mechanical properties, corrosion resistance, and ability to withstand high temperatures. This combination of metals results in a material that is both strong and durable, making it suitable for various demanding applications.

Applications

Heating Elements: Nickel chromium are commonly used to produce heating elements, such as those found in electric heaters, toasters, and industrial furnaces. Their high electrical resistance allows them to generate heat efficiently.

Aerospace: In the aerospace industry, nickel chromium canes are utilized for components that require high strength and temperature resistance, such as turbine blades and exhaust systems.

Chemical Processing: Due to their corrosion resistance, these canes are often employed in chemical processing equipment, including reactors, pipes, and heat exchangers, where exposure to harsh chemicals is common.

Oil and Gas Industry: Nickel chromium canes are used in downhole applications and components subjected to high pressures and temperatures, providing durability in harsh environments.

Automotive: In the automotive sector, these alloys are used for exhaust systems, turbochargers, and other components that require high-temperature resistance and strength.

Manufacturing: Ni/Cr 80/20 wt % are also used in manufacturing tools and dies, particularly in processes involving high wear and heat.