Nickel Chromium Aluminium Yttrium Alloy Nanoparticles

Nickel Chromium Aluminium Yttrium Alloy Nanoparticles

| Nickel Chromium Aluminium Yttrium Alloy Nanoparticles | |

| Product No | NRE- 2033 |

| CAS No. | 7440-02-0/7440-47-3 |

| Formula | NiCrAlY |

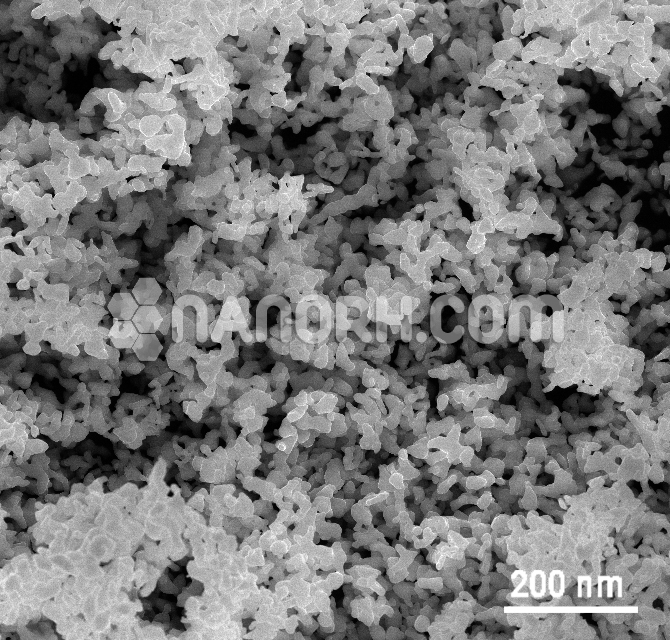

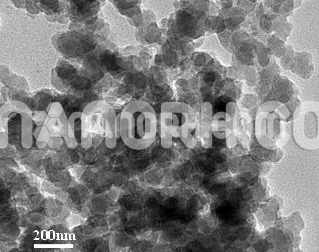

| APS | <100nm (Can be Customized) |

| Purity | 99.9% |

| Color | Grey |

| Molecular Weight | 226.57 g/mol |

| Density | 7.5 g/cm3 |

| Melting Point | 1400 °C |

| Boiling Point | NA |

Nickel Chromium Aluminium Yttrium Alloy Nanoparticles

Introduction

The development of advanced materials has become increasingly vital for a wide array of industries, from aerospace to electronics, energy storage, and biotechnology. Among the most promising materials in this domain are nanoparticles, which offer unique physical and chemical properties that differ significantly from bulk materials.

The Significance of Alloy Nanoparticles

Alloys are materials composed of two or more metals, which, when combined, often exhibit enhanced mechanical, thermal, and electrical properties compared to their constituent metals. By reducing the size of alloy particles to the nanoscale (typically between 1 and 100 nanometers), the material experiences a number of changes in its behavior.

Composition and Properties

The Ni-Cr-Al-Y alloy combines four important elements: nickel (Ni), chromium (Cr), aluminium (Al), and yttrium (Y). Each of these elements contributes distinct properties to the alloy:

Nickel (Ni): Nickel is known for its excellent resistance to corrosion and oxidation, high thermal stability, and good mechanical properties. It is widely used in the production of heat-resistant alloys, especially in the aerospace and automotive industries.

Chromium (Cr): Chromium is primarily added to enhance the material’s resistance to oxidation and wear. It is also responsible for imparting high hardness and strength to the alloy. When combined with nickel, chromium helps form a protective oxide layer on the surface of the material, further improving its corrosion resistance.

Synthesis and Fabrication

Mechanical Milling: This involves the physical grinding of bulk alloy powders to create fine nanoparticles. This method can control the particle size and the distribution of different alloy components at the nanoscale.

Sol-Gel Method: This is a chemical synthesis route that allows the creation of nanoparticles through the transition of a solution from a liquid ‘sol’ to a solid ‘gel,’ facilitating the uniform mixing of the alloy components. This method is particularly useful for controlling the nanoparticle size and ensuring the uniformity of the alloy’s composition.