| Nickel Chromium Alloy Sputtering Target | |

| Product No | NRE-43113 |

| CAS No. | NA |

| Formula | Ni-Cr |

| Molecular Weight | 110.6895 g/mol |

| Purity | 99.99% |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

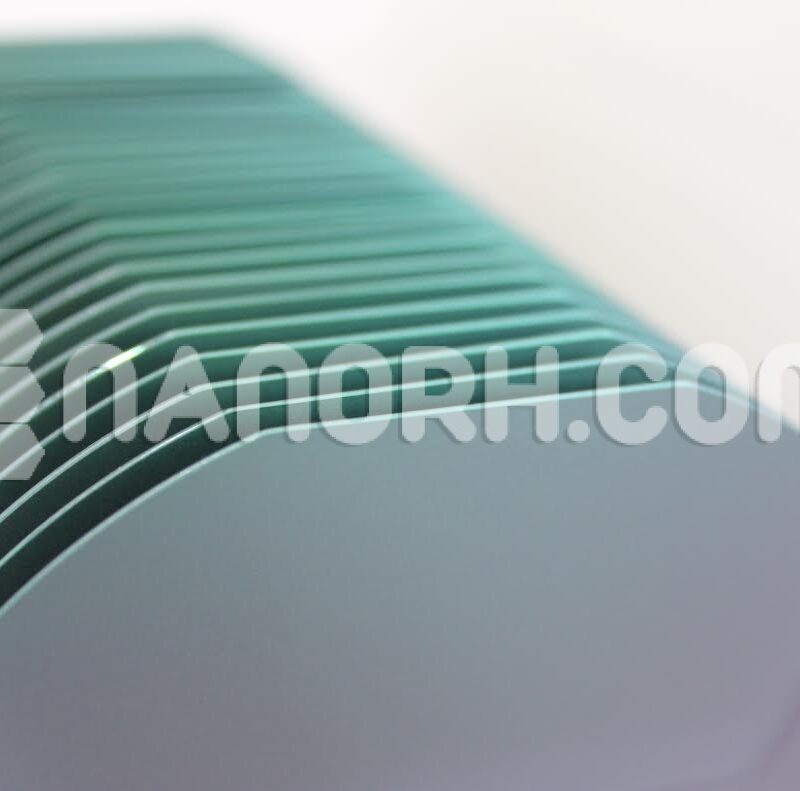

Nickel Chromium Alloy Sputtering Target

Introduction

Nickel chromium alloy sputtering target are composite materials composed primarily of nickel (Ni) and chromium (Cr). These alloys are well-known for their excellent corrosion resistance, high-temperature stability, and mechanical strength. Due to their unique properties, nickel chromium alloys are widely used in various applications, particularly in environments that demand durability and resistance to oxidation. The sputtering process allows for the deposition of these alloys as thin films on various substrates, facilitating their use in advanced technologies.

Applications

Protective Coatings:

Nickel chromium alloy coatings are commonly used to protect components from corrosion and wear in harsh environments, such as aerospace, automotive, and chemical processing industries.

Electrical Contacts:

These alloys are utilized in the production of electrical contacts and connectors due to their good electrical conductivity and resistance to oxidation, ensuring reliable performance in electronic devices.

High-Temperature Applications:

Nickel chromium alloys maintain their mechanical properties at elevated temperatures, making them suitable for applications in gas turbines, heat exchangers, and other high-temperature components.

Wear-Resistant Coatings:

The hardness and wear resistance of nickel chromium alloys make them ideal for coatings on cutting tools and industrial machinery, enhancing their lifespan and performance.

Surface Engineering:

Nickel chromium alloy sputtering targets are employed in surface engineering processes to improve the surface properties of various materials, such as enhancing corrosion resistance and overall durability.

Research and Development:

These targets are often used in academic and industrial research to study new materials and their properties, particularly in materials science and engineering applications.

Thermal Barrier Coatings:

Nickel chromium alloys can be applied in thermal barrier coatings for high-performance components, providing thermal protection and reducing heat transfer in extreme conditions.