Product No: NRE-9081

| Nickel-Based fluxed alloy powder | Grade | Chemistry | Size | Hardness |

| NiCrBSiFe Atomized | Ni20A | C:0.1;Si:3;B:1;Cr:1;Fe≤6;Ni:Bal | -150mesh+45um

-106+45um |

20 |

| Ni40A | C:0.3;Si:3;B:2;Cr:10,Fe≤15;Ni:Bal | -150mesh+45um

-106+45um |

40 | |

| Ni45 | C:0.4;Si:3;B:2.6;Cr:12;Fe≤15;Ni:Bal | -150mesh+45um

-106+45um |

45 | |

| Ni60 | Cr:18.5,Si:4.2,Fe:4.2,

B:3.3,C:0.7,Ni:Rem. |

-150mesh+45um

-106+45um |

60 |

Nickel Based Fluxed Alloy Powder

Introduction

Nickel-based fluxed alloy powder is a specialized form of nickel alloy that has been mixed with a fluxing agent to enhance the properties of the base metal in a variety of industrial applications. The inclusion of flux materials, such as boron, silicon, or phosphorus, into the nickel alloy powder helps improve the material’s performance during welding, brazing, coating, and other thermal processes. These fluxed powders are particularly valuable because they facilitate better bonding, increased flowability, and improved wetting characteristics during processes that involve high temperatures and reactive environments.

Nickel-based alloys, by nature, exhibit exceptional corrosion resistance, high-temperature strength, and oxidation resistance, making them ideal for demanding applications in industries like aerospace, automotive, marine, and chemical processing. However, the addition of flux agents significantly enhances their functionality in specific applications, particularly in joining processes like brazing or welding and coating applications. This creates a synergy between the properties of nickel alloys and the flux, resulting in alloys that perform optimally in complex, high-performance environments.

The process of fluxing involves the incorporation of reactive components that help remove impurities, such as oxides, sulfides, or dirt from the workpieces being joined. By creating a protective layer, flux not only prevents oxidation during heating but also promotes the flow of the molten alloy, ensuring a clean and strong bond. This property is particularly valuable in high-temperature applications where a clean, reliable joint is essential for structural integrity and long-lasting performance.

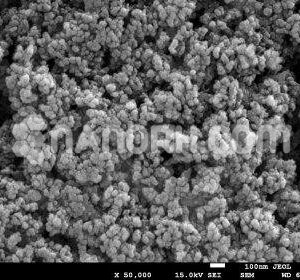

The powder form of the nickel-based fluxed alloy is typically produced through atomization, a process in which molten metal is rapidly cooled to form fine particles.