Nickel Aluminium Alloy Nanoparticles

| Nickel Aluminium Alloy Nanoparticles | |

| Product Number | NRE-2031 |

| CAS No. | 12635-29-9 |

| Formula | Ni-Al |

| Molecular Weight | 85.674 g/mol |

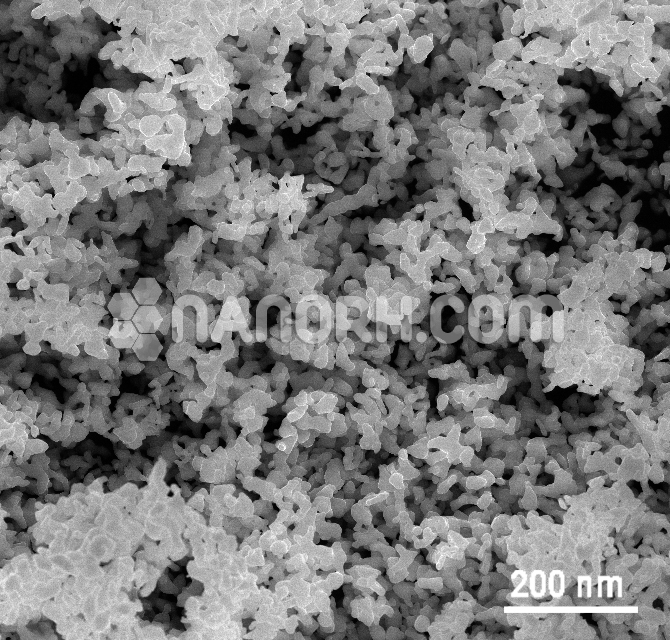

| APS | <100 nm (Can be Customized) |

| Purity | 99.9% |

| Colour | Gray |

| Density | 7.5g/cm3 |

| Melting Point | 1385 °C |

| Boiling Point | Na |

Nickel Aluminium Alloy Nanoparticles

Applications

Catalysis:

Hydrogenation and Dehydrogenation: Ni-Al alloys exhibit excellent catalytic properties, making them ideal for use in hydrogenation and dehydrogenation reactions. These reactions are important in industries such as petrochemical refining and pharmaceutical manufacturing.

Fuel Cells: Ni-Al nanopowders are explored as catalysts in hydrogen fuel cells, where they facilitate the conversion of hydrogen into electricity, offering an eco-friendly alternative to traditional energy sources.

Environmental Catalysis: Ni-Al nanoparticles are used in environmental catalytic processes, such as automotive catalytic converters, where they help reduce harmful emissions by converting toxic gases like carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances.

Energy Storage and Conversion:

Battery Materials: Ni-Al alloy nanoparticles are being investigated for use in batteries, particularly in lithium-ion batteries and supercapacitors. Their high surface area and enhanced conductivity improve charge storage and cycling stability.

Thermal Management: Ni-Al alloys can be used in thermal management applications, where they act as heat sinks or thermal conductors in electronic devices, engines, and industrial machinery.

Aerospace and Automotive:

Lightweight Components: The low density and high strength of Ni-Al alloy nanoparticles make them ideal for aerospace and automotive components, where weight reduction is critical for improving fuel efficiency and performance. Examples include turbine blades, brake components, and engine parts.

Wear-Resistant Coatings: Ni-Al nanoparticles are used in wear-resistant coatings for parts subjected to high friction and wear, such as in automobile engines and machine tools. These coatings help extend the service life of critical components.

Electronic and Magnetic Devices:

Conductive Films: Due to their electrical conductivity, Ni-Al alloy nanoparticles are used in electronic devices for the development of conductive films and circuit boards. Their use helps improve the efficiency and performance of devices.

Magnetic Sensors: Ni-Al alloys exhibit magnetic properties, making them suitable for use in magnetic sensors and data storage devices, such as hard drives and memory storage components.