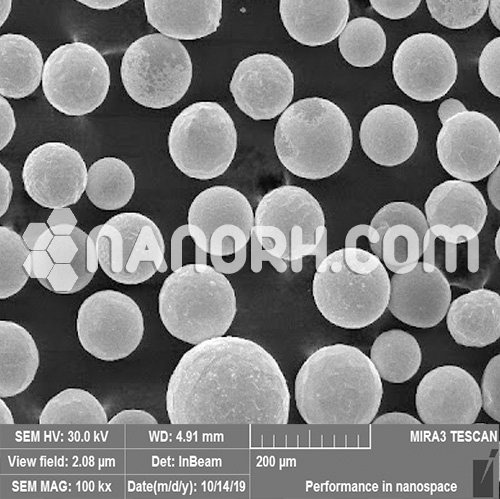

Nickel Alloy Powder

The main application of 3D printing metal powder;

Aerospace

Molds

Automotive

Medical instruments

Military industry

| Product No. | Nickel Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size |

| NRE-60006 | NRE-Inconel 718 | Ni50-55,Cr17-21,Mo2.8-3.3,Nb+Ta4.75-5.5, | 0.05-0.1 | 3.8-5.0 | 15-45 µm, 20-63 µm, 45-150 µm, D50 10-15 µm, D50 1-2 µm, D50 0.5-1 µm. |

| NRE-Inconel 625 | Cr20-23, Mo8-10 | ||||

| NRE-Hastelloy X | Cr20.5-23, Mo8-10, Fe17-20 | ||||

| NRE-Hastelloy C | Cr15-16.5, Mo15-17, Fe40,W3-4.5,Co1.5-2.5 | ||||

| NRE-Invar | Ni35-37,Fe Bal | 3.5-4.5 | |||

| NRE-Kovar | Ni28.5-29.5, Co16.8-17.8, Fe BalCu3-5, | 3.0-4.5 |

Nickel Alloy Powder

Applications

Aerospace Industry:

Turbine Components: Nickel alloy powder like Inconel 718 are used to 3D print turbine blades, rotors, and stators in jet engines and gas turbines. These components must withstand extreme temperatures and pressures, making the high-temperature resistance of nickel alloys critical.

Exhaust and Combustion Parts: Nickel alloys are used in exhaust systems, nozzles, and combustion chambers, where resistance to heat, pressure, and oxidation is vital.

Heat Shields and Thermal Management: Parts in aerospace applications that require excellent thermal resistance, such as heat shields, can be made with nickel alloys to protect components from extreme temperatures.

Energy Sector:

Power Plant Components: Nickel alloys, especially Inconel 625, are widely used in power plants to 3D print components like heat exchangers, pressure vessels, and turbine blades. These parts are exposed to high pressures, temperatures, and corrosive fluids, which makes the alloy’s resistance to thermal stress and corrosion essential.

Nuclear Industry: Nickel alloys are also used in nuclear reactors for components like reactor cores and coolant systems. These alloys’ resistance to radiation, heat, and corrosion makes them suitable for use in these harsh environments.

Oil and Gas Equipment: Nickel alloys are used for parts like valves, pumps, and offshore drilling equipment, where resistance to corrosion from saltwater and high-pressure environments is crucial.

Chemical Processing:

Corrosion-Resistant Parts: Nickel alloys such as Hastelloy and Monel are frequently used in the chemical industry to 3D print components like reactors, valves, pumps, and piping systems. These alloys’ resistance to acids, alkalis, and other aggressive chemicals makes them ideal for harsh chemical environments.

Heat Exchangers: In the chemical processing industry, heat exchangers made from nickel alloys can endure high temperatures and corrosive environments, maintaining efficiency and reliability.