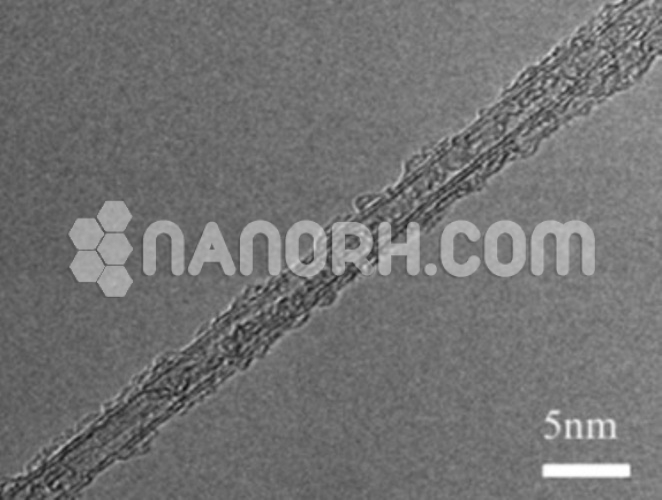

| Multi Walled Carbon Nanotubes | |

| Product No | NRE-34009 |

| CAS No. | NA |

| Purity | Carbon nanotubes > 95wt% |

| Average Diameter | 10-30 nm |

| Average Length | 10-30 um (TEM) |

| Special Surface Area(SSA) | 180m2/g(BET) |

| Tap Density | 0.27g/cm3 |

| True Density | 2.1g/cm3 |

| Electric Conductivity | > 100 S/cm |

| Thermal Conductivity | 15 W/mK |

Multi Walled Carbon Nanotubes

Applications:

Electronics and Conductive Materials

Electrodes in Energy Storage Devices:

MWCNTs are used in supercapacitors, batteries, and fuel cells due to their excellent electrical conductivity and high surface area. In supercapacitors, MWCNTs serve as conductive electrodes that enhance charge storage capacity, leading to improved energy storage efficiency and longer cycle life. They are also used in lithium-ion batteries to improve the performance of electrodes and increase energy density.

Conductive Inks for Printed Electronics:

MWCNTs are incorporated into conductive inks for printed electronics. These inks can be used to print flexible circuits, sensors, and RFID tags on substrates like plastic, paper, or textiles. MWCNT-based inks provide excellent conductivity and are used in the production of flexible and wearable electronic devices.

Transparent Conductive Films:

MWCNTs are also used to produce transparent conductive films, which are essential for applications in touchscreens, solar cells, and displays. These films combine the electrical conductivity of MWCNTs with their transparency, making them ideal for use in optoelectronic devices.

Nanocomposites and Advanced Materials

Reinforcement in Polymers and Composites:

MWCNTs are widely used to reinforce various materials, including polymers, metals, and ceramics, in a process called nanocomposite fabrication. Adding MWCNTs to polymers significantly improves the material’s mechanical strength, thermal stability, and electrical conductivity. Applications include automotive parts, aerospace materials, sports equipment, and protective coatings. The result is lightweight materials that are stronger and more durable than conventional composites.

Conductive Coatings:

MWCNTs are used in coatings to enhance electrical conductivity, corrosion resistance, and thermal properties. They are commonly applied in electromagnetic shielding and anti-static coatings. These coatings are used in electronics, military equipment, and automotive parts to protect sensitive components from electromagnetic interference and environmental damage.