| Molybdenum Sputtering Target | |

| Product No | NRE-43109 |

| CAS No. | 7439-98-7 |

| Formula | Mo |

| Molecular Weight | 95.95 g/mol |

| Purity | >99 % |

| Density | 10.28 g/cm³ |

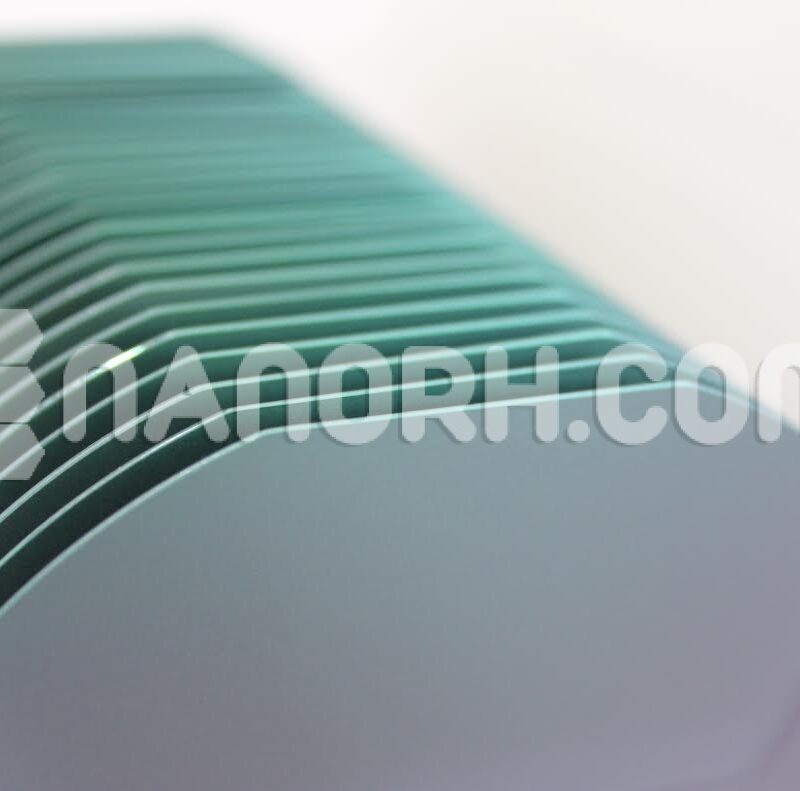

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Expansion | NA |

Molybdenum Sputtering Target

Molybdenum sputtering targets are utilized across a diverse range of applications due to their unique properties, including high melting point, excellent conductivity, and corrosion resistance. Here are some of the key applications of molybdenum sputtering targets.

Electronics

Thin Film Transistors (TFTs): Used in flat-panel displays, molybdenum serves as a conductive layer in TFTs, ensuring efficient performance and stability.

Interconnects in Integrated Circuits: Molybdenum is employed in microelectronics as an interconnect material, facilitating electrical connections between different components.

Optoelectronics

Photovoltaic Cells: Molybdenum thin films are used in solar cells, particularly as back contact layers, to enhance energy collection and improve efficiency.

Optical Coatings: Molybdenum films are applied as coatings on lenses and mirrors, where their reflective properties are utilized in various optical devices.

Aerospace and Defense

High-Temperature Components: Molybdenum is used in components that operate under extreme temperatures, such as turbine blades in jet engines and heat shields in spacecraft.

Structural Materials: Its high strength-to-weight ratio makes molybdenum suitable for aerospace structural applications, where durability is critical.

Wear-Resistant Coatings

Tool Coatings: Molybdenum can be applied as a protective coating on cutting tools and machinery components to enhance wear resistance and extend their lifespan.

Industrial Equipment: Used in coatings for various industrial equipment to improve durability and reduce maintenance costs.

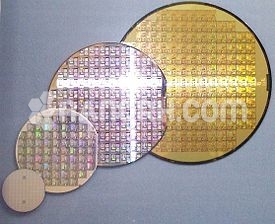

Semiconductors

Gate Contacts in MOSFETs: Molybdenum is utilized as a gate contact material in metal-oxide-semiconductor field-effect transistors (MOSFETs), where its conductivity is advantageous.

Source and Drain Contacts: Employed in other semiconductor devices for efficient charge transport.

Catalysis

Hydrogen Production: Molybdenum-based catalysts are investigated for use in hydrogen evolution reactions (HER), contributing to sustainable energy technologies.

Chemical Reactions: Used in various catalytic processes in the chemical industry, such as hydrodesulfurization.

Additive Manufacturing

3D Printing: Molybdenum is explored as a material for 3D printing in high-performance applications, leveraging its thermal and mechanical properties.

Magnetic Materials

Magnetoresistive Devices: Molybdenum can be used in thin films for magnetic applications, such as sensors and data storage devices.

Research and Development

Thin Film Studies: Molybdenum sputtering targets are frequently used in laboratories for research on thin film properties and behavior, aiding the development of new materials.