|

Molybdenum Gallium Carbide MAX Phase Powder |

|

| Product No. | NRE-58009 |

| CAS No. | NA |

| Formula | Mo2Ga2C |

| Molecular Weight | 343.33 g/mol |

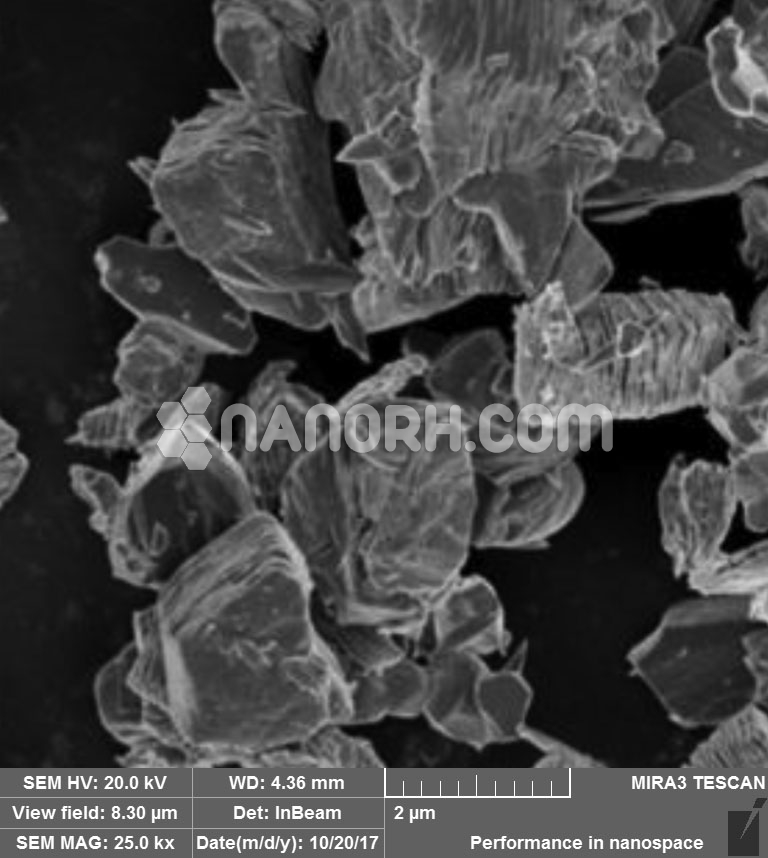

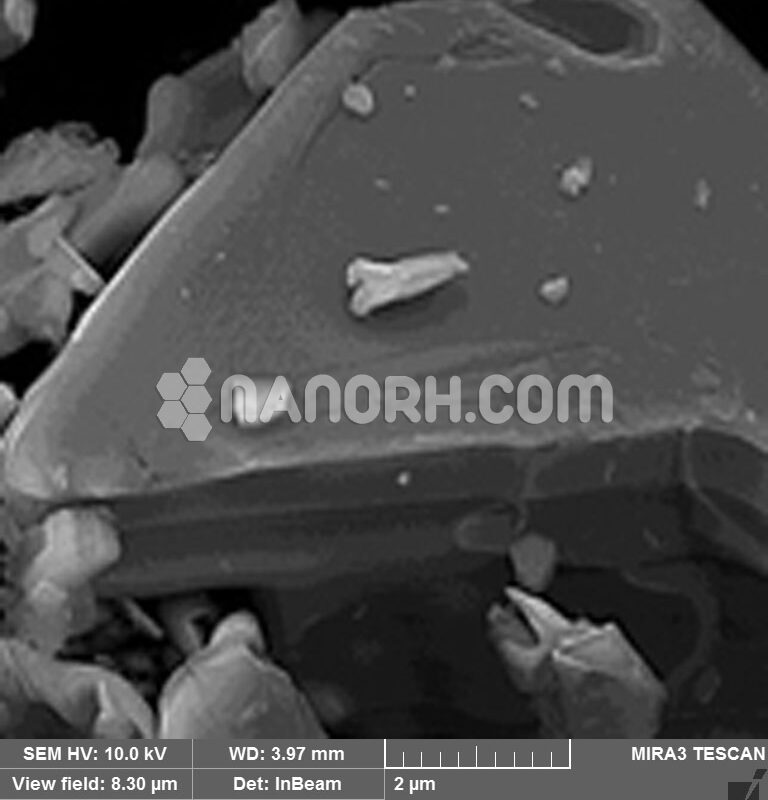

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

|

Certificate of Analysis |

|

| Mo | 55.9% |

| Ga | 40.6% |

| C | 3.4% |

| Sn | 0.03% |

| Cr | 0.02% |

| O | 0.01% |

| Fe | 0.03% |

Molybdenum Gallium Carbide MAX Phase Powder

Molybdenum gallium carbide Mo2Ga2C is a member of the MAX phase materials, which are a family of ternary carbides and nitrides with unique properties. MAX phases are known for their combination of metallic conductivity and ceramic-like hardness. Here’s how Mo2Ga2C powder is used in various product applications:

High-Temperature Structural Materials

Application: High-temperature and wear-resistant coatings and components.

Role: Mo2Ga2C is valued for its high melting point, thermal stability, and mechanical strength. It is used in applications where materials are subjected to extreme temperatures and harsh environments. Mo₂GaC powders can be used to create coatings or components that maintain their properties under high-temperature conditions.

Advanced Tooling

Application: Cutting tools and machining components.

Role: Due to its hardness and wear resistance, Mo2Ga2C is used in tooling applications, including cutting tools and inserts for machining. The material’s durability makes it suitable for demanding manufacturing processes where high performance is required.

Electrical Contacts

Application: Electrical contacts and conductive components.

Role: Mo2Ga2C exhibits good electrical conductivity, making it suitable for use in electrical contacts and conductive components. Its stability at high temperatures and resistance to oxidation enhance the performance and longevity of electrical contact materials.

Thermal Barrier Coatings

Application: Thermal barrier coatings for engines and turbines.

Role: The thermal stability of Mo2Ga2C makes it suitable for thermal barrier coatings that protect underlying materials from high temperatures. These coatings are used in engines, turbines, and other high-temperature equipment to improve performance and longevity.

Catalysis

Application: Catalysts for chemical reactions.

Role: Mo2Ga2C can serve as a catalyst or support material in various chemical reactions. Its unique combination of metallic and ceramic properties can enhance catalytic activity and stability in certain reactions.