| Molybdenum Crucibles | |

| Product No | NRE-47014 |

| CAS No. | 7439-98-7 |

| Formula | Mo |

| Molecular Weight | 95.94 g/mol |

| Purity | 99.9% |

| Density | 10280 kg/m3 |

| Melting Point | 2623 °C |

| Boiling Point | 4639 °C |

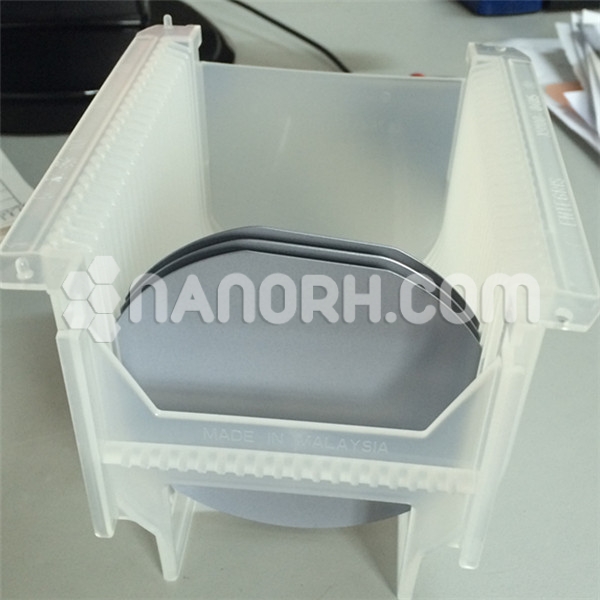

| Shape | Crucible |

| Electrical Resistivity | 5.2 microhm-cm @ 0 °C |

| Electronegativity | 1.9 Paulings |

Molybdenum Crucibles

Introduction:

Molybdenum crucibles are high performance containers made from molybdenum, a refractory metal known for its excellent thermal conductivity, high melting point, and resistance to thermal shock. These crucibles are designed to withstand extreme temperatures and harsh chemical environments, making them ideal for various specialized applications, particularly in metallurgy and materials science.

Applications

Metallurgical Processes:

Melting and Casting: Widely used for melting high-temperature metals and alloys, including tungsten and certain high-performance alloys, due to their ability to withstand extreme heat without deformation.

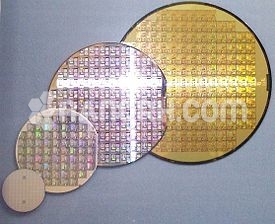

Crystal Growth:

Employed in the growth of single crystals, particularly in the production of semiconductors and optical materials, where precise control of temperature is critical.

Sintering:

Used in the sintering process for various materials, including ceramics and advanced composites, to achieve desired material properties through controlled heating.

Nuclear Applications:

Applied in nuclear reactors and other nuclear-related processes for handling radioactive materials, thanks to molybdenum’s high-temperature stability and low neutron absorption cross-section.

Laboratory Research:

Commonly utilized in research settings for high-temperature experiments, especially in studies involving reactive or corrosive materials.

Electronics:

Used in the semiconductor industry for processes that require high temperatures and inert environments, such as the deposition of thin films.

Thermal Treatment:

Employed in heat treatment applications for metals, where high thermal resistance is required to achieve specific material properties.

Coating Processes:

Utilized in physical vapor deposition (PVD) processes to create coatings on various substrates, where molybdenum’s properties help in achieving high-quality results.