| Molybdenum Boride Sputtering Targets | |

| Product No | NRE-43498 |

| CAS No. | 12007-27-1 |

| Formula | Mo2B |

| Molecular Weight | 117.6 |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

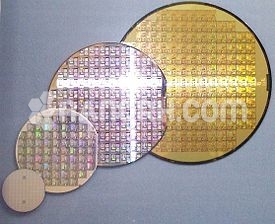

Molybdenum Boride Sputtering Targets

Introduction

Molybdenum boride sputtering targets are materials used in thin film deposition processes, known for their exceptional hardness, thermal stability, and chemical resistance. This compound combines the beneficial properties of molybdenum and boron, making it suitable for various high-performance applications in materials science and engineering.

Applications

MoB is utilized to create ultra-hard coatings that enhance the wear resistance of tools and components, making them ideal for machining and cutting applications.

Electrical Contacts:

Employed in the fabrication of electrical contacts and interconnects, leveraging its excellent electrical conductivity and thermal properties.

Protective Coatings:

Used in protective coatings for components exposed to harsh environments, such as in aerospace and automotive industries, providing corrosion resistance and durability.

Thermal Barriers:

Suitable for applications requiring thermal barrier coatings, helping to improve the thermal management of components in high-temperature environments.

Research and Development:

Frequently employed in R&D to explore new materials and their properties, contributing to advancements in nanotechnology and advanced materials.

Conclusion

Molybdenum boride sputtering targets play a vital role in various high-performance applications across multiple industries. Their unique combination of hardness, stability, and conductivity makes them valuable materials in modern manufacturing and research, paving the way for innovative solutions in advanced technologies.