| Molybdenum Boride Powder | |

| Product No | NRE-11181 |

| CAS No. | 12006-98-3 |

| Formula | MoB |

| Density | 9.20 g/cm3 |

| APS | <40µm (Can be Customized) |

| Purity | 99.9% |

| Form | Powder |

| Molecular Weight | 106.751 g/mol |

| Certificate Of Analysis | |

| Mo | 89.8% |

| B | 10.1% |

| Cr | 0.02% |

| Fe | 0.03% |

| O | 0.02% |

| Sn | 0.01% |

| Ti | 0.01% |

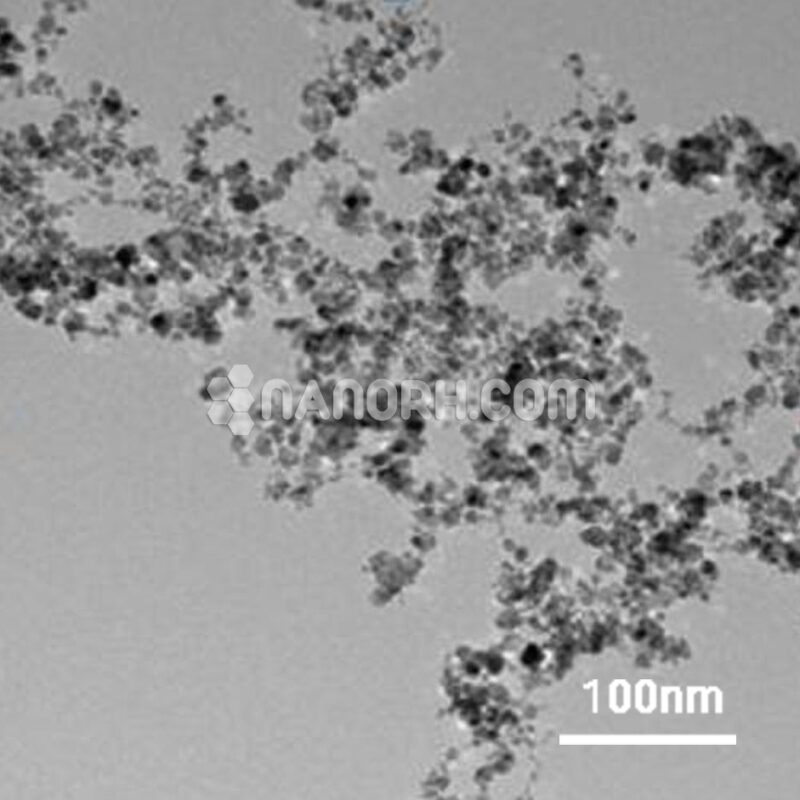

Molybdenum Boride Powder

Molybdenum boride powder is a compound that has gained attention due to its unique properties and potential applications in various fields. Molybdenum boride typically refers to two different compounds: molybdenum boride (MoB) and molybdenum boride (Mo2B). Here are some potential applications of molybdenum boride powder:

High-Temperature Applications: Molybdenum boride powders are known for their high melting points and excellent thermal stability. They can be used as a coating material for high-temperature applications, such as in aerospace components, turbine engines, and other equipment that operates under extreme heat conditions.

Hard Coatings and Wear-Resistant Materials: Molybdenum boride powders can be utilized to create hard coatings and wear-resistant materials. These coatings can be applied to cutting tools, drills, and other machinery components that undergo wear and tear, enhancing their durability and extending their lifespan.

Catalysts: Molybdenum boride powder can be used as a catalyst in various chemical reactions. Its unique properties make it suitable for catalyzing certain processes in industries such as petrochemicals, refining, and chemical manufacturing.

Electronics and Semiconductors: Molybdenum boride powder has shown promise in the field of electronics and semiconductors. It can be used as a potential material for electrodes, contacts, and other electronic components due to its high conductivity and thermal stability.

Refractory Materials: Due to its high melting point and resistance to heat, molybdenum boride powder can be used in the production of refractory materials. These materials are used in furnaces, kilns, and other high-temperature applications where materials must withstand extreme heat without deforming or degrading.

Additive Manufacturing: MoB powders can be utilized in additive manufacturing processes, such as 3D printing, to create complex and durable components for various industrial applications.

Research and Development: MoB powder is also used in research and development for its unique properties, especially in the field of materials science. Researchers are exploring its potential applications in various emerging technologies and industries.