Molybdenum Aluminum Carbide MAX Phase Powder

Molybdenum Aluminum Carbide MAX Phase Powder

|

Molybdenum Aluminum Carbide MAX Phase Powder |

|

| Product No. | NRE-58008 |

| CAS No. | NA |

| Formula | Mo3AlC2 |

| Molecular Weight | 338.82 g/mol |

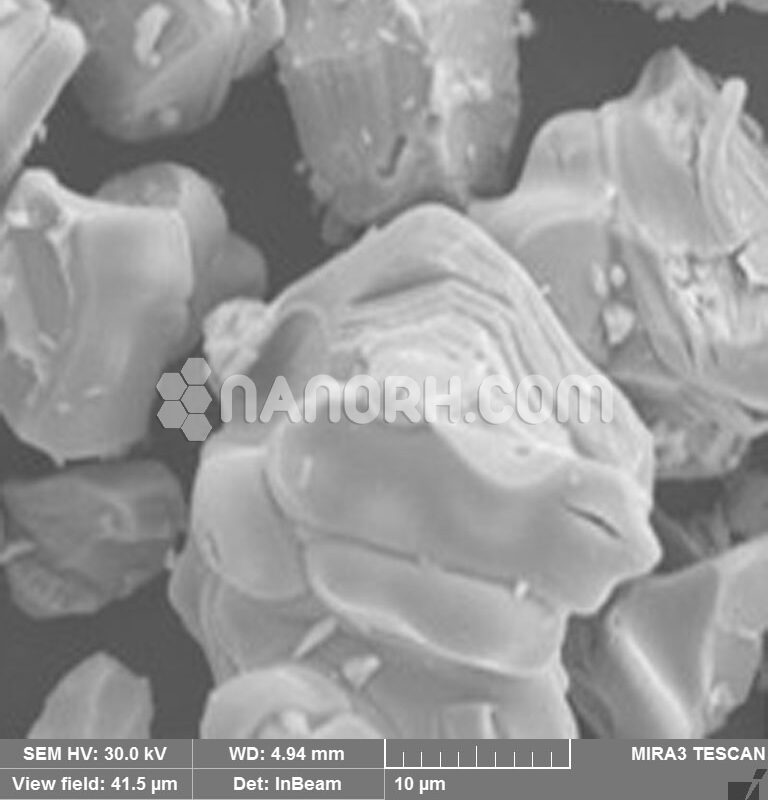

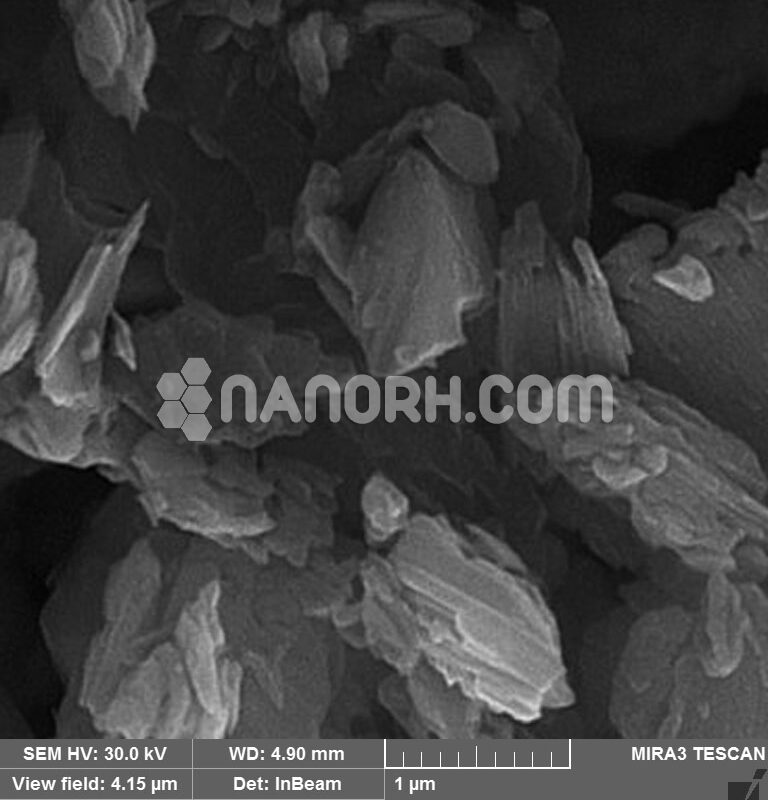

| APS | < 40 μm |

| Purity | 99.9% |

| Form | Powder |

|

Certificate of Analysis |

|

| Mo | 84.9% |

| Al | 7.9% |

| C | 7.1% |

| Fe | 0.03% |

| Cr | 0.02% |

| O | 0.01% |

| Sn | 0.03% |

Molybdenum Aluminum Carbide MAX Phase Powder

Properties of Mo₃AlC₂

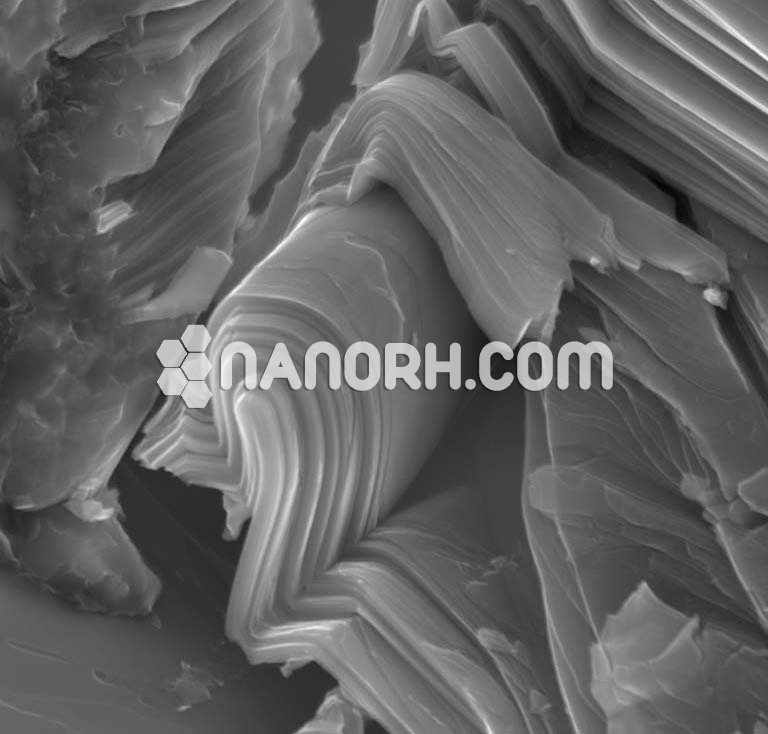

Layered Structure: The layered structure of Molybdenum Aluminium Carbide MAX Phase Powder contributes to its unique combination of properties. This structure allows for easy dislocation movement, resulting in high damage tolerance and the ability to deform plastically.

Electrical Conductivity: Molybdenum Aluminium Carbide MAX Phase Powder exhibits good electrical conductivity, a property inherited from its metallic components.

Thermal Conductivity: It has high thermal conductivity, making it an excellent material for applications requiring efficient heat dissipation.

Mechanical Properties: Mo₃AlC₂ combines the hardness and high-temperature stability of ceramics with the ductility of metals. This results in a material that is both tough and resistant to thermal shock.

Oxidation Resistance: One of the notable properties of Mo₃AlC₂ is its resistance to oxidation at high temperatures, attributed to the formation of a protective oxide layer on its surface.

Applications of Mo₃AlC₂

High-Temperature Structural Components: Its ability to maintain structural integrity at high temperatures makes it suitable for components in aerospace and power generation industries.

Electrical Contacts and Conductors: The material’s good electrical conductivity is beneficial for applications in electrical and electronic components.

Thermal Management Systems: The high thermal conductivity of Mo₃AlC₂ is advantageous for heat sinks and other thermal management applications.