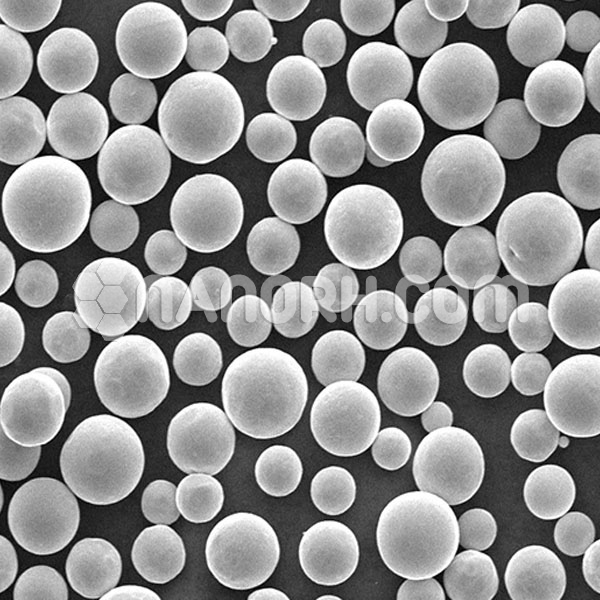

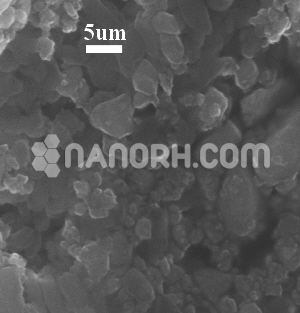

| Mg-Zn alloy powder Spherical | |

| Product No | NRE-60101 |

| Purity | 99.9% |

| Mesh | 30-500 mesh |

| Color | Silver Gray |

| Product | Ratio Mg: Zn | Real density(g/cm³) | Calorific value(J/g) |

|

Atomized spherical Mg-Zn alloy powder |

70:30 | 2.26 | 18110 |

| 30:70 | 3.47 | 11180 | |

| 50:50 | 2.83 | 15050 | |

| 20:80 | 4.23 | 9240 | |

| 10:90 | 5.25 | 7300 | |

| 90:10 | 1.92 | 24110 | |

| 95:5 | 1.82 | 24136 |

Mg-Zn alloy powder Spherical

Key Features of Spherical Mg-Zn Alloy Powder:

Lightweight:

Magnesium is the lightest structural metal, and the addition of zinc allows for a low-density material with improved mechanical properties.

Mg-Zn alloys are ideal for lightweight components used in industries such as automotive, aerospace, and electronics.

Corrosion Resistance:

Zinc improves the corrosion resistance of magnesium alloys, making them suitable for applications in marine environments, automotive components, and aerospace parts that are exposed to harsh conditions.

The corrosion resistance of Mg-Zn alloys is further enhanced by surface treatments and coatings.

High Strength-to-Weight Ratio:

Mg-Zn alloys provide an excellent strength-to-weight ratio, meaning they are strong and durable while being lightweight.

Applications

Additive Manufacturing (3D Printing):

The spherical shape of the powder allows for its use in 3D printing technologies like Selective Laser Melting (SLM), Electron Beam Melting (EBM), and Direct Energy Deposition (DED). These technologies are employed to create complex, lightweight, and high-performance parts with precise geometries.

Applications include customized aerospace parts, automotive prototypes, and functional parts with complex geometries.

Powder Metallurgy:

Spherical Mg-Zn alloy powder is ideal for use in powder metallurgy to manufacture automotive components, gears, brakes, and other lightweight structural parts.

Automotive Industry:

Mg-Zn alloys are commonly used in automotive parts to reduce the overall weight of vehicles while maintaining strength and durability.

Examples include engine components, chassis parts, wheels, and brackets where weight reduction contributes to improved fuel efficiency and lower emissions.

Battery casings for electric vehicles (EVs) benefit from the corrosion resistance and lightweight nature of Mg-Zn alloys.

Aerospace Industry:

Mg-Zn alloy powder is used to produce lightweight, strong, and corrosion-resistant parts for aerospace applications, such as aircraft structural components, engine parts, and heat exchangers.

The low density of the alloy contributes to fuel efficiency and reduced operational costs in both aircraft and spacecraft.