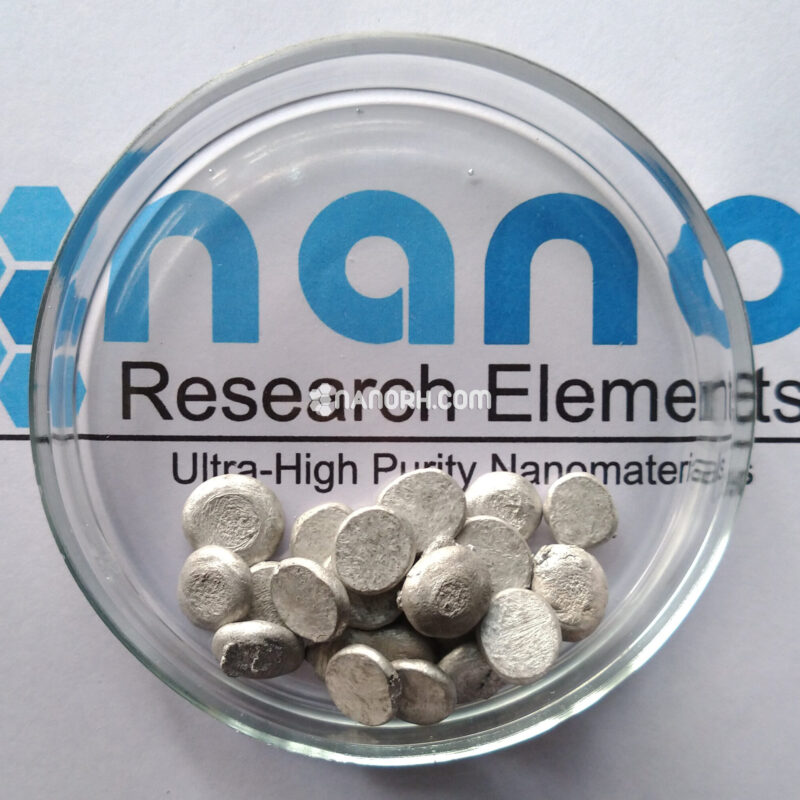

| Lutetium Oxide Sputtering Targets | |

| Product No | NRE-43487 |

| CAS No. | 12032-20-1 |

| Formula | Lu2O3 |

| Molecular Weight | 397.93 |

| Purity | >99.9% |

| Density | NA |

| Thickness | 3 mm ± 0.5mm (can be customized) |

| Diameter | 50 mm ± 1mm (can be customized) |

| Shape | Round |

| Resistivity | NA |

| Thermal Conductivity | NA |

Lutetium Oxide Sputtering Targets

Introduction

Lutetium oxide (Lu2O3) is a rare earth compound with a range of unique properties that make it suitable for various advanced applications, particularly in the fields of electronics, optics, and materials science. As a sputtering target, lutetium oxide is utilized in thin-film deposition processes to create high-quality films for various technological applications.

Properties of Lutetium Oxide

High Purity: Lutetium oxide can be produced with high purity, which is essential for electronic and optical applications.

High Refractive Index: It exhibits a high refractive index, making it valuable for optical coatings and components.

Thermal Stability: Lutetium oxide is thermally stable, allowing it to withstand high-temperature processing conditions.

Electrical Insulator: It serves as a good insulator, making it useful in semiconductor applications.

Applications

Optical Coatings: Used in the production of anti-reflective coatings, lenses, and mirrors to enhance performance in optical devices.

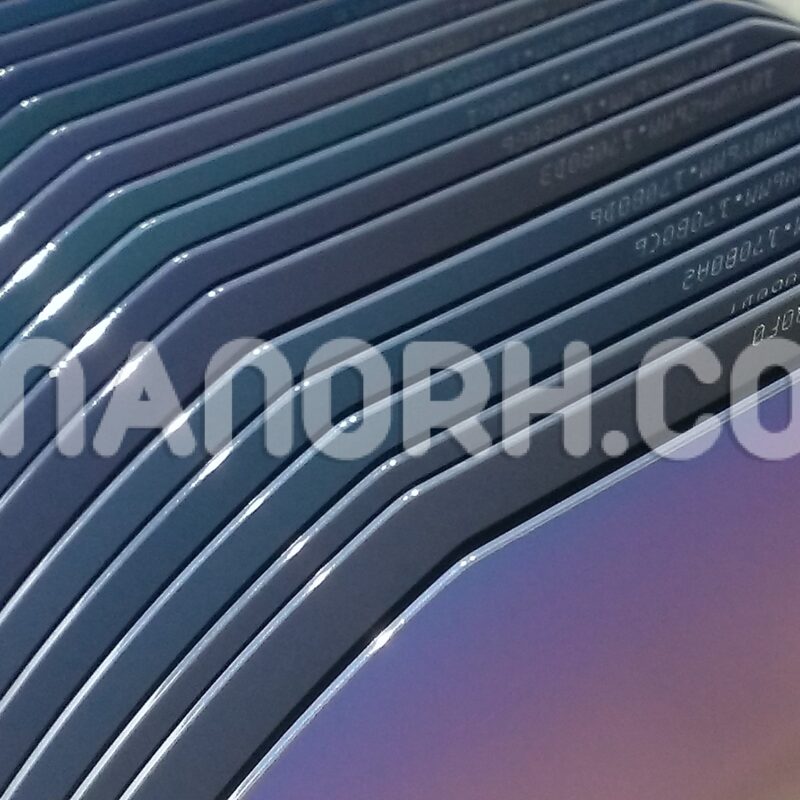

Semiconductor Industry: Lutetium oxide can be applied in the fabrication of thin films for semiconductors, particularly in gate dielectrics and insulating layers.

Phosphors: It is often used in the manufacture of phosphor materials for lighting and display technologies.

Luminescent Materials: Due to its luminescent properties, it can be used in various optoelectronic devices.

Magnetic Applications: Lutetium oxide is also explored in the context of magnetic materials and devices.

Sputtering Process

In sputtering, a target material (in this case, lutetium oxide) is bombarded with energetic particles, causing atoms to be ejected from the target surface. These ejected atoms then deposit onto a substrate, forming a thin film. The control over film thickness, composition, and microstructure makes sputtering a preferred method for thin-film deposition.